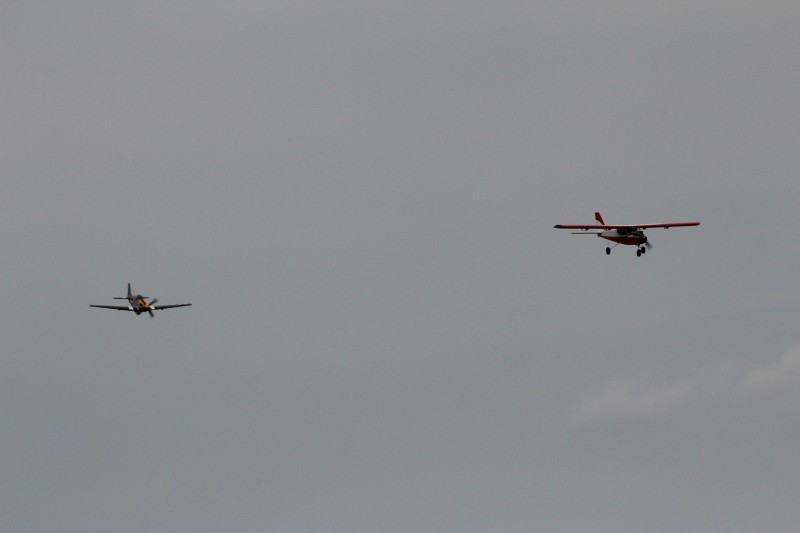

As I think I mentioned in my last post, I really dislike the idea of having the 3 blade assembly on the Motion RC/Flightline RC P-38 being held together by the plastic back plate of the spinner and self tapping screws set into that plastic. In order to eliminate this, I started looking at options.

I first thought I would simply purchase some one piece 3 blade props… but upon further study I realized that the spinners supplied with the kit were customer made and would not directly support such props. Finding spinners that were appropriate would be possible but expensive and for all that expense I’d still have 3 blade props which are not my favorite from an efficiency perspective…

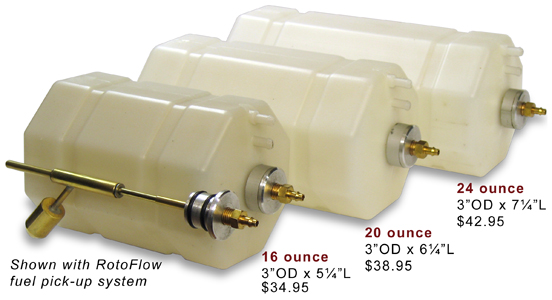

My next thought was that perhaps I just purchase the 2 blade spinners and props from Motion RC that are provided as part of their sport power set? The only issue is that the props are 12×8 two blade versus the 12×7 three blade set that is the standard set. I want something approaching the same load and speed profile as the original if at all possible. So the root question is what size and pitch prop in a 3 blade is most similar to the 12×7 stock 3 blade prop?

A bit of research revealed a loading factor can be calculated for any prop with the following formula:

PL=D*D*D*P*(square root(B-1) where PL=Prop Loading, D=diameter, P=pitch, and B=blade count.

Using this formula to calculate the loading factor of the stock props and then comparing to similar calculated factors for 2 blade options plus or minus an inch or two should give some propeller options that would be suitable.

In the course of measuring to see what options were possible due to ground clearance (I estimate anything up to a 14″ diameter would be reasonable) I found that the factory prop is actually about 6.25 inches in radius. Based on that I adjusted to a 12.5 inch diameter for my reference point.

After loading in several prop sizes it became obvious that a 12×8 two blade was a far less appropriate match than a 13×8. The 13×8 is less than a 1% load differential from the reference point while the 12×8 is 22% less load. This means that the 12×8 propellers available from Motion RC just aren’t suitable for my purposes… not with the stock motors. Based on past experience, it is highly likely that the difference between the stock prop and any other manufacturers similarly sized prop will vary by far more than this small percentage just due to blade shape and composition so, no guarantee but I think it will be close enough for my purposes.

This means I need both standard and reverse pitch 13×8 props and spinners. Note that the spinners must be be cut to match the pitch direction so just 2 standard spinners won’t work here either. Looking into all this, it appears the cost to get this all done is not exactly going to be cheap… So maybe a flight or two with the 3 blades is in order to determine just how much I dislike this setup! Maybe the plane will fly poorly enough that I won’t really want to spend the money… 🙂

Just as I was about to hit “publish” on this post I was assembling the propellers for both the green and silver aircraft when I had a problem that added yet another wrinkle…

As I was putting in one of the final screws on the final propeller assembly (for my green bird) one of the screws sheared off before it even got tight against the prop! Here’s a picture of the result:

I’m a bit concerned, wondering if the other screws are all this weak? Just when I was thinking maybe these assemblies would be OK… This did not add to my comfort level. I’m really in a quandary now as to which way to go.