After making the previously documented adjustments I had some on line conversations with the local WWI enthusiasts and found that one of the reasons my Bristol flew so poorly was likely related to adverse yaw. I took it back out and flew it and I could obviously tell this was the case.

For those lucky enough not to experience it, here is my attempt to demystify a bit. Yaw is the motion around the vertical and along the horizontal axis that causes the nose of the airplane to point left or right. This is typically provided by the use of rudder… at least when it’s intentional! Adverse yaw is the motion that occurs around the vertical axis when you roll the aircraft by the use of ailerons. For instance, when you attempt to roll and turn to the left the left aileron will extend to the top of the wing and the right aileron will extend to the bottom (downward if the plane is upright). Both ailerons will immediately increase the overall drag of the airplane but in some cases (especially on flat bottom airfoils) the downward motion of one aileron creates more drag than the aileron that extends to the top (upward) side. If you think about what that means, the pilot is attempting to roll and turn right (for instance) but the drag on the left wing aileron extending downward is pulling the nose to the left! This is not the direction of motion the pilot intends, thus it is adverse! The quick fix is to input rudder in the direction of the intended turn. This can be done either by the pilots input or by creating a mix. Either can work, but I’m not a fan of this solution no matter which way you implement it.

It seems to me we have a problem that is created by an excessive amount of drag on one side of the plane that we now plan to correct with more drag applied to the other side of the air frame. More drag means the airplane slows and we get closer to stall. Depending on how close we already are to stall… this can be bad. Of course if more power is available we can overcome this problem but we are just adding more complication and more difficulty to make all these forces balance out. The pilot’s chances of correcting with just the right amount of rudder and power while executing a turn in an aircraft experiencing adverse yaw are decreased markedly versus an aircraft that does not have this issue. I want a smooth coordinated turn, not a wiggling, jerky, abrupt maneuver that looks like the pilot has had to much to drink, so I decided to use the aileron differential feature of my radio and let it handle this for me.

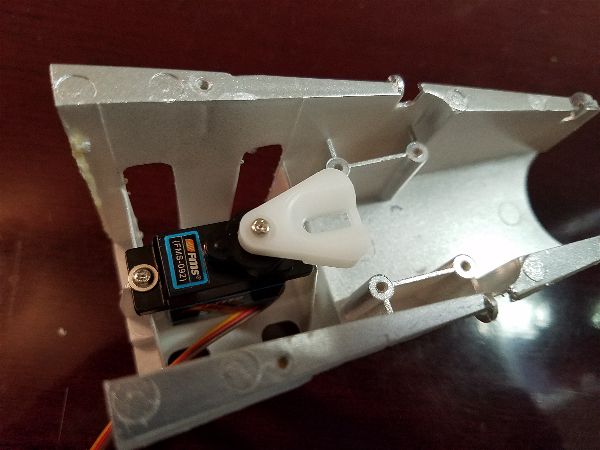

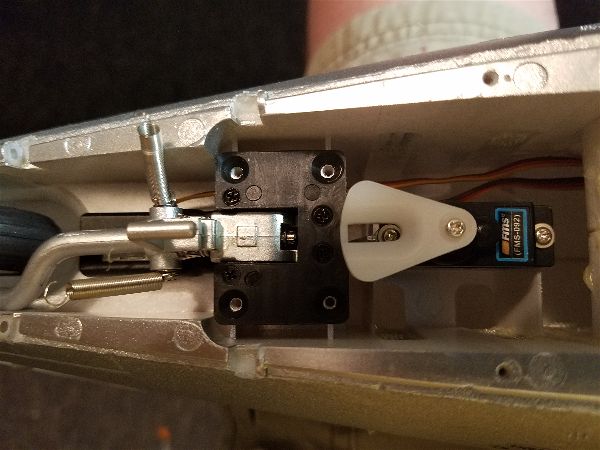

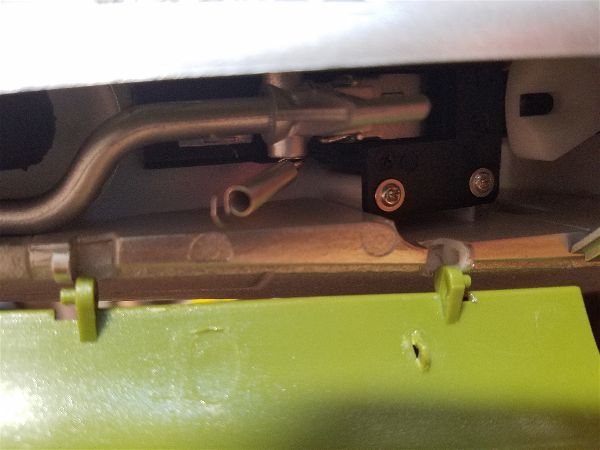

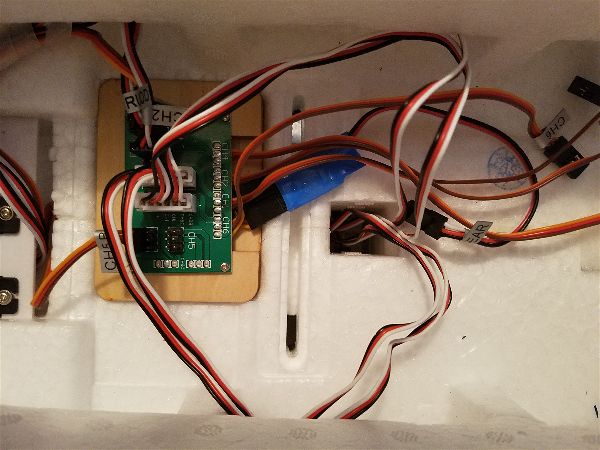

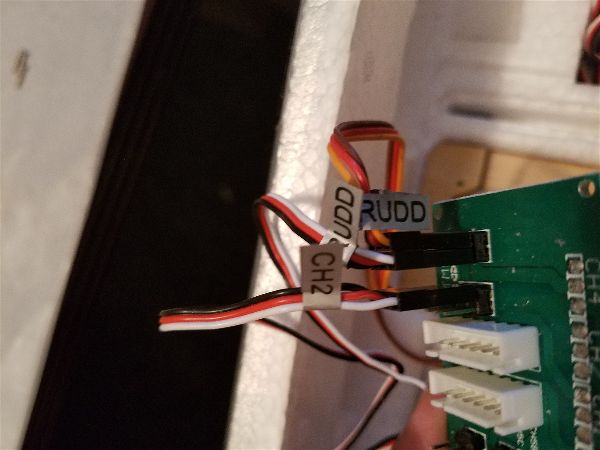

Aileron differential requires that the two aileron servos be connected on two different channels so they can be controlled independently. By programming differential the two ailerons will extend by different amount. So when the port (left) aileron goes up, the starboard aileron goes down but by a lesser amount. Less down means less drag and the nose is not pulled toward this side and the maneuver can be completed without the necessity of rudder input. Some rudder may be desirable for things like a coordinated turn but that is a whole different topic.

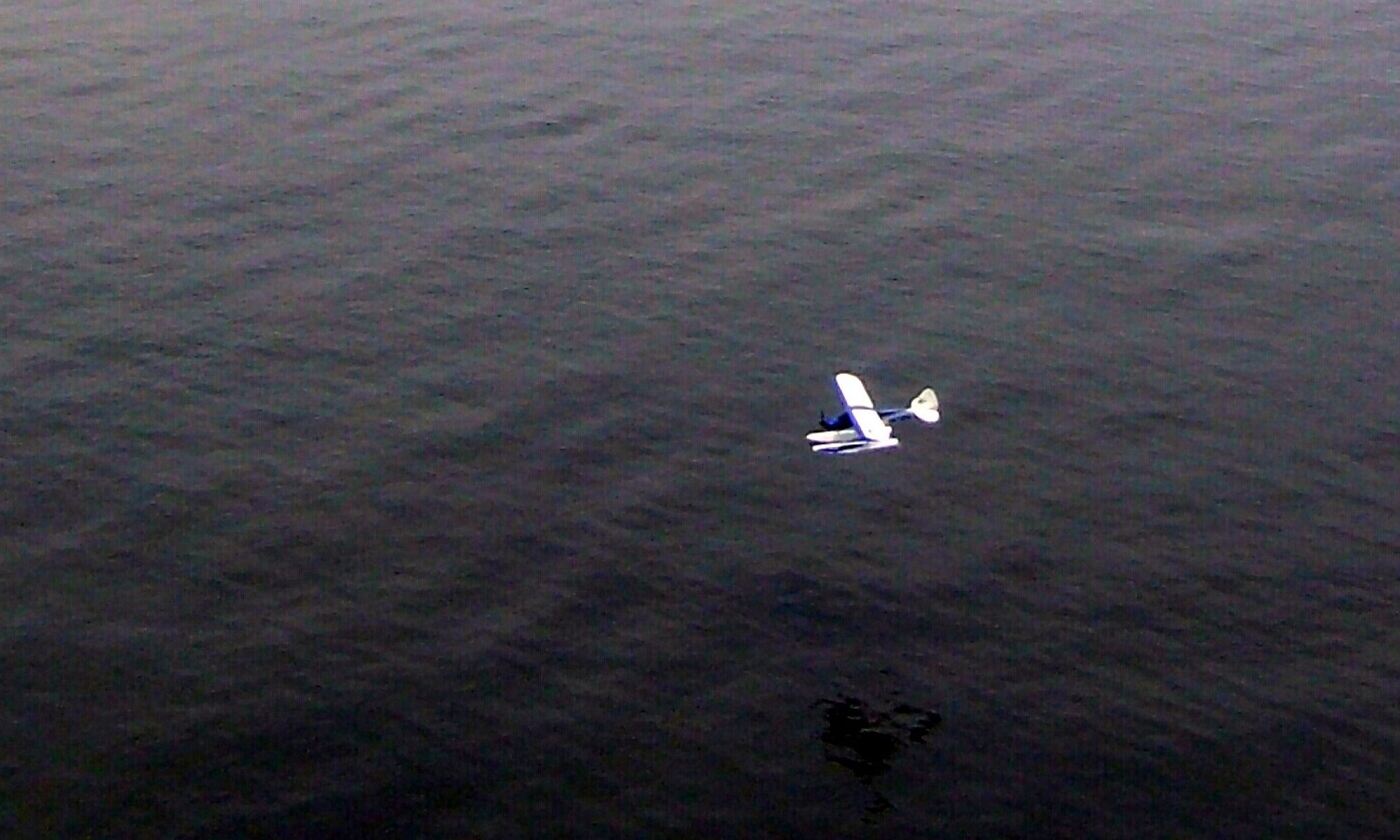

For the Bristol this was the final piece of the puzzle that made it fly the way it should. At least the way it should as I understand it! A return to the field for more tests and the adverse yaw seemed to be under control.

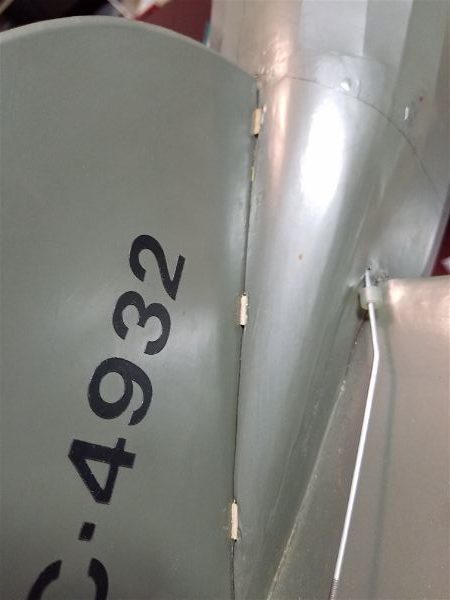

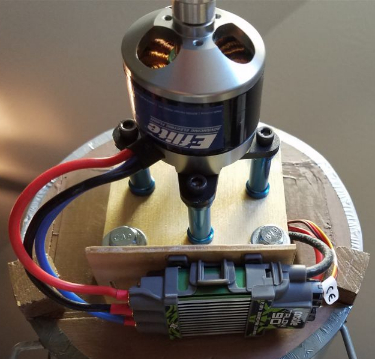

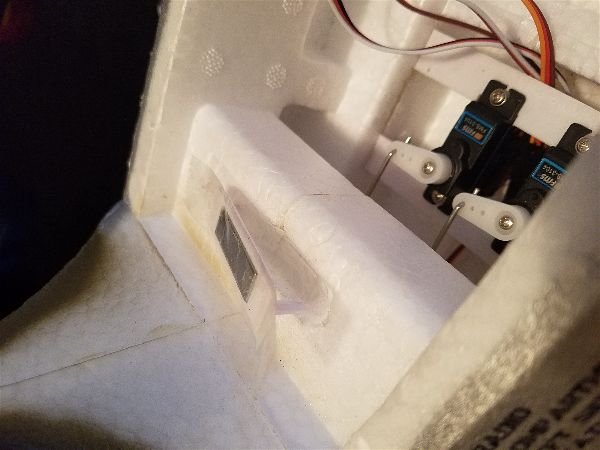

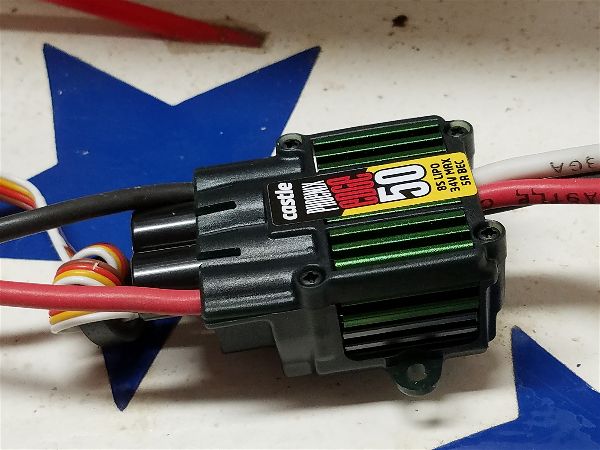

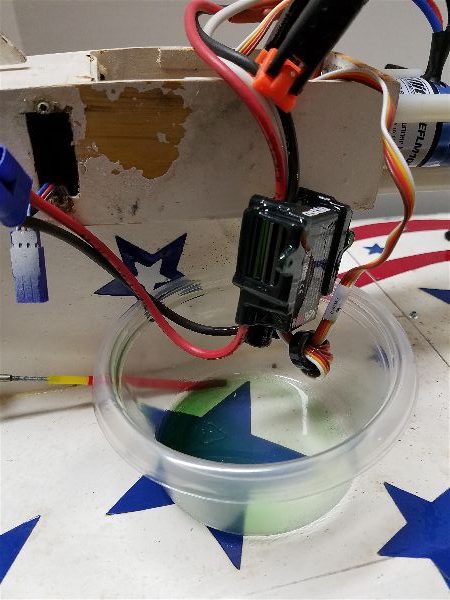

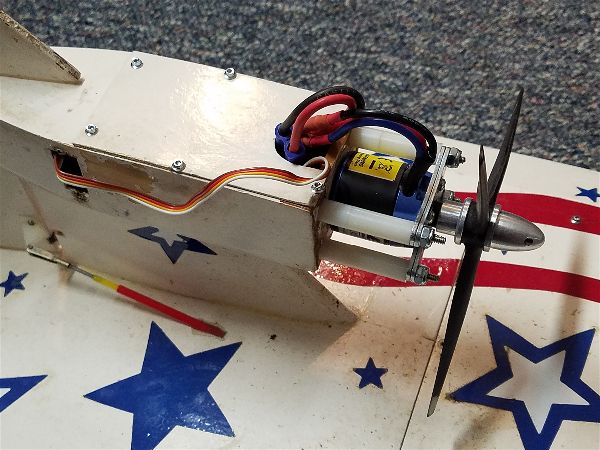

After all of this I began to realize that this airplane would never fly up to my hopes and expectations. It is a WWI design after all and it just will never be what I regard as a “good flying” airplane. It’s nice to watch it fly… and I had no problem getting it up and down and performing the basic aerobatics that it is designed for but it was not a floater (which I enjoy) nor a precise maneuvering acrobatic ship. It just always feels like its slogging along to me. For that reason I am in the process of stripping the power system and electronics and will pass it on to someone who is more interested in this type of airplane and can really appreciate it for what it is. So long Bristol.