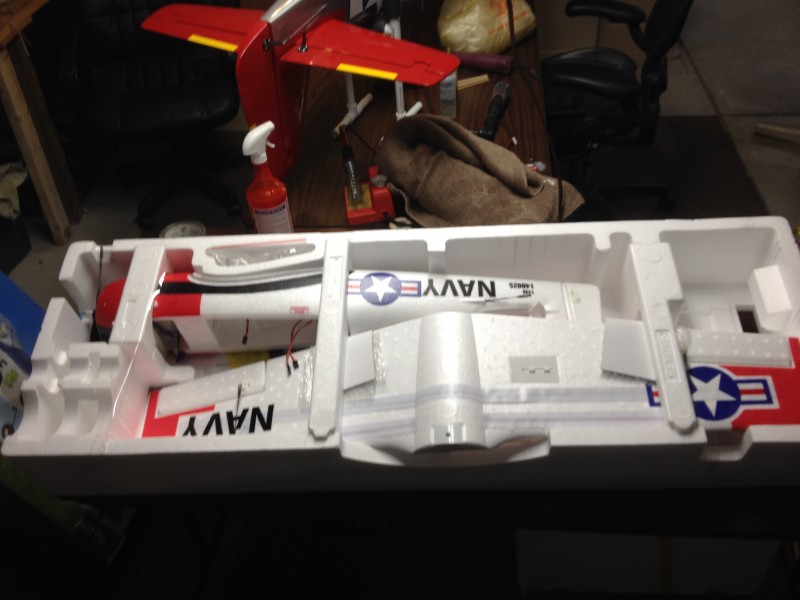

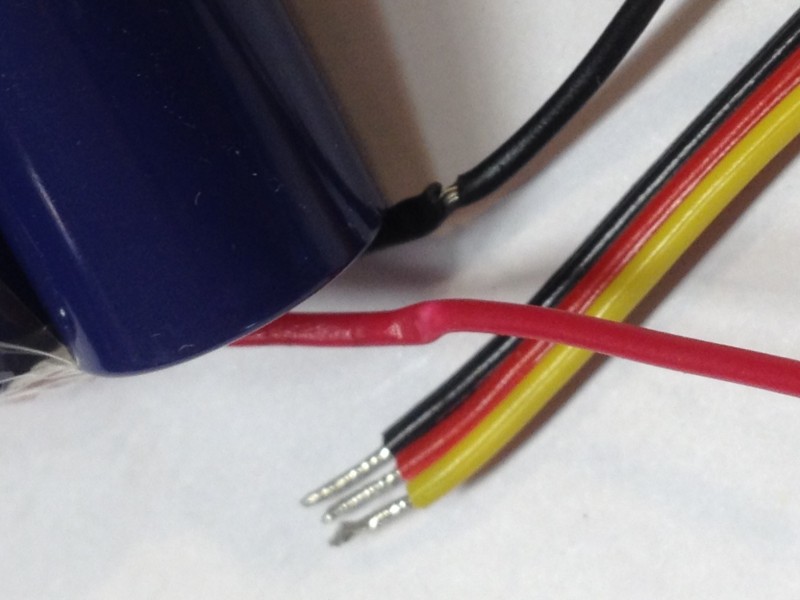

In the last 2 weeks I’ve had the Mustang up on 6 flights and put it back in “race ready” condition just in time for our annual Tim Mills Derby Days RC Airshow. This is just a little wrap up of the updates I’ve made and issues I’ve had since building up a new wing and electrifying the Robart retracts. I will come back and edit this post with a few added photos in the coming days.

Working more or less chronologically, I got the wing built up and the retracts installed along with installing the retractable tail gear in the fuselage. All seemed to be working pretty well so I went out for the first flight. It went well, with “Drag Racer 2” going through her paces just I remembered. She flies heavier than anything else I fly but with no real handling problems or bad habits other than needing a lot of speed to handle well. Fairly much what you’d expect from a big war bird. Maybe the ailerons could be dialed up a bit but the rolls are probably pretty close to scale… maybe a second or a bit more to complete a roll?? I’ll have to check that and consider increasing throws on those.

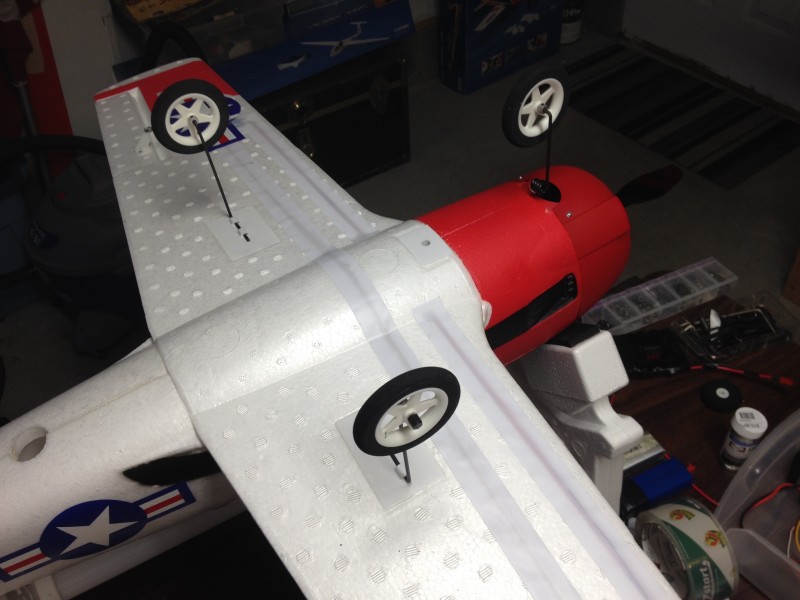

This first flight, I kept the gear down and the landing was fairly uneventful with the exception of a tendency to turn right as the roll out got slow. Nothing that the rudder couldn’t correct. The landing gear took the shock on landing better than I expected. A pleasant surprise.

Second flight a half hour later was a bit more exciting… After the first couple laps I hit the retract switch and all three disappeared into the bottom of the airplane as planned. So far so good, except the plane wanted to climb rapidly. At first I didn’t understand but soon the reality of removing drag and closing the majority of the large pockets in the bottom of the tail and wing set in. The plane is just getting more lift and experiencing less drag… which equates to the tendency to climb. That’s generally a good thing so why fight it. Eventually, a couple flights later, I trimmed it for level flight with the gear up and just got used to pulling a little up when flying with the gear extended.

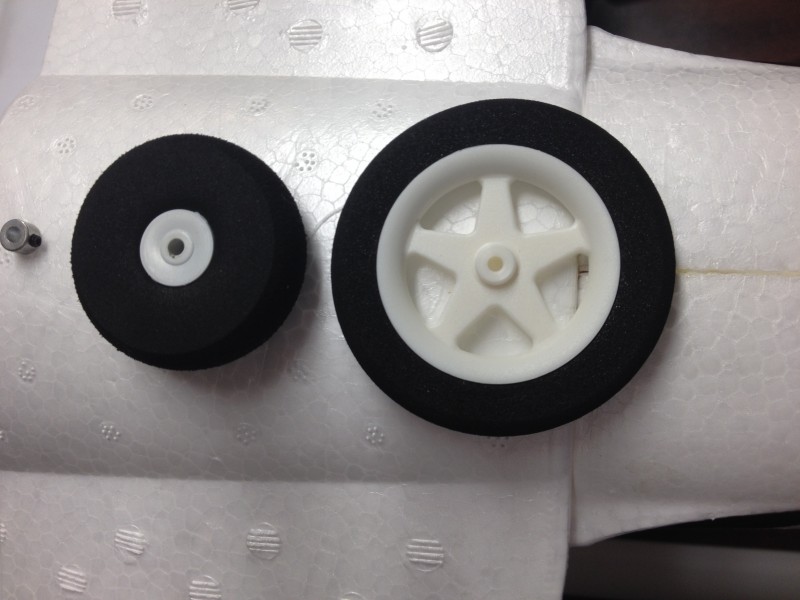

After a few high speed passes I decided it was time to land and went for the retract switch again. A quick pass to check gear down and… uh-oh… only 1 main is down! While having all sorts of awful thoughts about how a Mustang would land on no gear (22 lbs of airplane on the scoop… yikes!) or even worse with only one main gear I tried cycling the gear a couple times. Eventually I had the two mains down and locked. The tail gear also managed to jam part way down but I decided to live with that and brought it in smoothly again. No damage and now it is obvious that the gear door is pivoting on the strut and getting caught on the edge of the wing inset.

Back in the shop to tighten and re-glue the doors and come up with a solution for the tail wheel jam issues. The problem seemed to be that the cables that steer the wheel go slack when retracted. This allows the tail wheel to pivot around in flight and get caught against the side of the plane when the command comes to move. After some consideration, I added some rubber bands to the assembly to hold the wheel straight when no servo linkage pressure is being applied. This keeps the axle and wheel from contacting the insides of the fuse OR the landing gear doors when coming down.

Back at the field a few days later and it was time for flight 3 and 4. These two flights went well and it was during these that the trim got adjusted to account for the wheels up “slick” condition of the airframe in normal cruising mode. As I flew, I got more and more comfortable with the airplane and made some “photo” passes in near knife edge and about 20-50 foot altitudes as well as fast low passes, immelmans, loops, split S(s), aileron rolls… Pretty much anything you’d expect a Mustang could do. Both landings were smooth with comments from a pilot who owns this same ARF (not modified and with the wire gear on) to the effect that I was making him look bad by coming in to land so smoothly. I love to see a big bird do a nice landing so I spend extra time and effort to make mine look good when I can.

Also during these flights I noticed just how much slicker the plane is with the gear up. I was expecting 2-3… maybe 5 mph increase in speed. What I got was 10-12! In a couple of cases the GPS on board said I had hit 113, almost 114 in a shallow dive toward the field. Before anyone comments on the inaccuracy of GPS speed, I can tell you I have tested the GPS versus the Pitot tube type instrument and they are very consistently within 1-2 mph of each other. Engine RPMs hit somewhere around 7500 at their highest which didn’t seem to harm the DA-50 at all.

Those flights went very well and the landings were nice with full flaps and just a click or two of power on landing. Back in the shop I painted the mounting blocks to match the struts and added the guns to the leading edge. Two .50 cal in each wing in this B/C model (unlike the 3 per wing in the D). The guns I did a bit different this time. I cut circles out of flat black and then circles out of those big enough for the gun barrels. I then ironed these covering “donuts” onto the leading edge at the appropriate spots and then drilled in the donut hole so the gun barrels could be expoxied in place. After all was complete, a little flat black paint to cover up the brass tubes from which they are fabricated and all is ready to go. There seems to be quite a variance in gun installations in different Mustang models so these look good enough and much better than the factory glue on pieces.

About the only thing left for this bird is more flights and some added epoxy on a couple of cowl screw inserts that are walking out. I’m actually getting past the knee knocker factor of flying this bird and starting to enjoy it for what it is. Not my favorite or best flying aircraft, but very impressive in the sky with plenty of wow factor for the crowd.