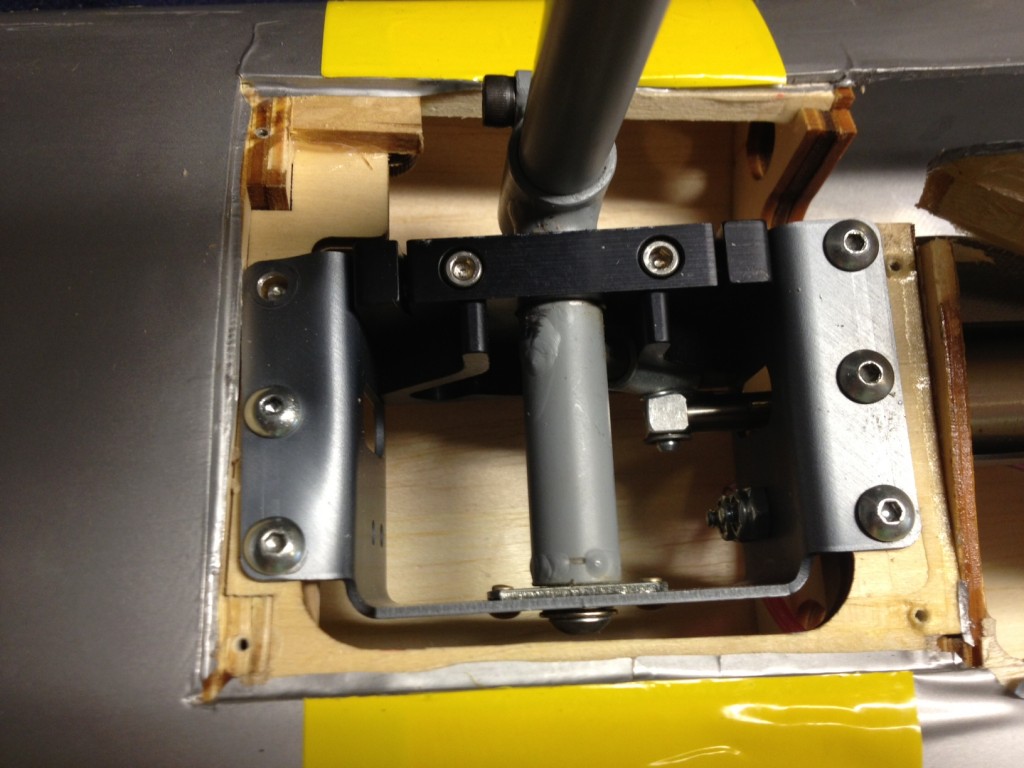

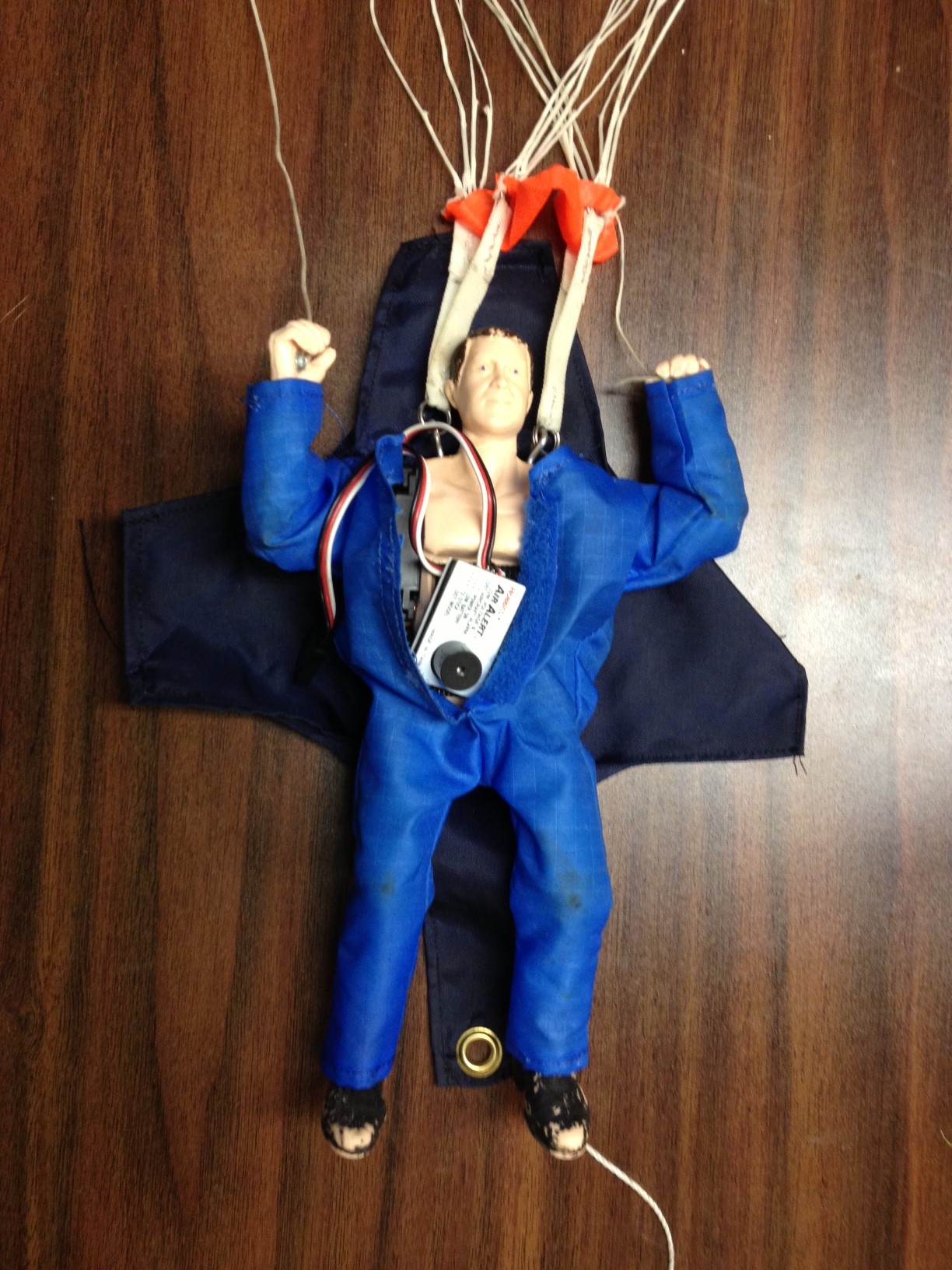

Had a nice day flying at our Annual Toys for Tot’s charity fundraiser yesterday and today did the recharge on the flight packs on the plane I flew. This particular plane has a pair of A123 2300mah batteries that plug directly into my Spektrum PowerSafe 9110 receiver. This thing is a $200 item but it’s main feature is the ability to plug two batteries directly into the receiver via high current EC3 type connectors. With this method the power supplied to the servos is shared between the packs and does not have to go through any switches. A soft switch is used, which means if the switch fails the airplane is on and the current to run the servos does not pass through the switch so it is not a limiting factor in supplying power to the high torque digitals that are used on all flight surfaces of this aircraft.

When I went to recharge the batteries I started with the port side pack (just because) and charged them up to full… they took about 850mah. That seemed high as I flew maybe 3 or 4 times and none were much over 7-8 minutes. As I moved to the starboard pack something even more interesting occurred. The charger said no battery was present!! Double checking the leads quickly lead to the discovery that the negative lead ended in a nice solder ball that was no longer attached to the battery! At some point it had become disconnected… I don’t know if it was vibration, poor solder joints (from the manufacturer… I didn’t have a hand in this connection) or some combination of the two.

I have no way to know if this happened before the flight or during but I can tell by the fact that the second battery took only 100mah or so to charge that I made several flights without it! If the connection was dead before I took off the first time… then it really would have only meant I wouldn’t have flown that plane on that day if I hadn’t had this system. If it broke at some point during the first flight it likely means my airplane is only here today due to having the redundancy in the system. Glad I had this system.

Of course, this receiver is not the only way to get this level of redundancy and reliability. There are other power distribution systems out there but for this size and type of airplane I think its a very nice option and one I will probably continue to deploy. I will have to look at my pre-flight and assembly routine to see if there is a way I can check for this failure mode in the future. In the meantime its nice to know its there protecting me and my airplane from disasters.