RC Aviation

My local hobby shop, Hobby RC, got my replacement body and decal set in quickly and so the process of making this craft flight worthy again could begin!

Immediately upon unpacking a couple of things became obvious. As you can see here:

The decal set I ordered would not be necessary. Unfortunately the picture on the web site showed the spare part without the graphics. I’m happy this is the case but could have saved $15 if I’d known.

Next I noticed the rudder was not attached and I had no idea to this point how it was attached… the original came on my plane… I’m pretty sure…

Turns out the rudder just clips onto the body by the use of built in plastic clips and pins built into the two parts. You simply push it on and it pops in place… Couldn’t be much simpler.

After screwing on the two halves the elevator with the 4 black screws.

I pushed the rudder on and started flexing it back and forth when I noticed that it didn’t allow for much throw (I had been thinking it needed a bit more) plus I noticed that it tended to flex the elevator joiner, resulting in some deflection… that had to change. So taking advantage of that easy removal, I popped it back off and opened up the pass through slot with a sanding drum on my electric rotary tool. You can see how tight it is here in the before photo:

Quite a bit of material needs to be removed to get a significant amount of throw AND keep the pressure off the elevator joiner. Here’s the old and new with the modification.

And here is what it looks like installed.

This allows for the maximum throw allowed by the factory servo and linkage setup without binding. Sliding the push rods back in place and installing the servos on the rails was pretty straight forward. I notice the servos have no rubber grommets on the tabs… though I suppose in a foam body electric, vibration problems are fairly limited so no need.

This allows for the maximum throw allowed by the factory servo and linkage setup without binding. Sliding the push rods back in place and installing the servos on the rails was pretty straight forward. I notice the servos have no rubber grommets on the tabs… though I suppose in a foam body electric, vibration problems are fairly limited so no need.

While I was working on the tail, I flipped the plane over and went to work reinstalling the retractable tail gear. Only something was missing!

The plastic insert that everything mounts into was not in the new body… time for some surgery on the old body again… You can see here that it takes a lot of carving to get this thing out.

And here is the piece that comes out. It takes a little cleanup from here. You need to get all the foam off of it to easily insert it into the new body.

After getting the plastic insert into the new body, mounting the servo followed by the retract itself was pretty straight forward.

Mounting the servo and retract outside the aircraft is more straight forward than it was taking it out while still inside the tail of the plane. Route the wires (easier if you have “grabber” like the one you see here) and with a little glue on the contact points with the foam just slide the assembly back in place and we are back in business.

Reattach the doors and springs (a little bending/adjustment is likely needed) and everything goes back together fairly easily.

Next I reinstalled servos and the control board with it’s associated plywood tray inside the fuselage as well as the connector boards in the wing root. You’ll want to check your notes or photos on which wires plug into what as the labeling is helpful but not completely obvious. Once again I ran into a small issue where my notes and pictures were insufficient.

Here is the starboard wing root

Note the one socket is closest to the trailing edge of the wing. As you reinstall the matching plate in the body, be conscious of this and note that the port side is opposite… I just “assumed” that both would be installed similarly and it turns out not to be so.

Most everything else went back in with no issues, though I encourage you to take copious notes and photos if you have to do this for yourself. It will help immensely to guide you in the rebuild, knowing which screws to use, etc…

As I was assembling for final adjustment of the servo linkages and testing I found one more casualty. Here are two of the wing screws…

As you can see there was a bit of force exerted when one of the wing tips found the ground. These bolts are a little bit soft (which worked in my favor in this case!) so I was able to simply use some padding around the bolt in order not to mar the threads and bend it back into shape with pliers.

I made a final “rebuild” step by peeling the custom graphic for my crew chief (my Grandfather) and successfully reapplied it to the the new fuselage. Welcome home Grandpa!

While the P-47 was in the shop, a few additions were also made. With the addition of a telemetry module and associated sensors (GPS, G Force and Voltage sense wire…) I’ll be able to keep a better eye on my battery pack voltage, ground speed and other interesting tidbits.

This last weekend we had a nice event at the club field during which I got in 6 or 7 flights. After a bit of elevator trim during the first flight, the Bonnie proved she was back in peak form. Her pilot took another flight or two to get back in the groove… I did make sure that the battery was securely attached to the battery tray before each flight and I may add additional measures to be sure the whole assemble does not leave the plane prematurely. For now just being sure the straps on the tray also engage the hook and loop material on the battery seems to be working.

The FMS 1500mm P-47 continues to be my favorite flying War bird that I’ve ever flown. Because this is true, it has gotten quite a few flights in the past few months. But now there’s going to have to be some repairs before any more flights occur.

The P-47 flies so well that I tend to push it a bit from time to time and such was the case the other day as I lazily cruised around inverted and enjoyed the inherent stability of the air frame. When I needed to get back upright I pushed a bit of extra power and pushed a moderately tight outside 1/2 loop… Unfortunately at that point the battery decided to exit the airplane, in the process pushing off the canopy and of course disconnecting itself from the rest of the aircraft in the process! Yikes!

After that there was much confusion. The airplane rolled to upright (which I was trying to do) and stalled nose down at about 250 feet. At first I thought I had occasional and/or partial control so I continued to do what I tell everyone else to do… “Keep flying the biggest piece!” The airplane porpoised quite a bit and every time the nose came up I jammed in some down and it righted itself (yes, I know I was merely spectating at the time but I kept trying!). This continued and the airplane also turned back toward the runway as I intended and actually ended up landing only 10 feet or so off the mowed part of our runway near “show center”. Unfortunately the last porpoise up and stall was from about 10 feet and it hit moderately hard on the lower part of the cowl.

I can’t be absolutely certain, but my best guess is the battery slipped from the hook and loop straps, leaving the tray in the plane while the battery pushed the hatch off and bailed out! The tray was laying next to it in the grass. I believe ejected on impact.

What follows is a photo catalog of the damage incurred and the various disassembly I have done since in preparation for the replacement of the main body. The impact (I maintain the rule that you can’t call it a landing if you should say impact…) made a couple cracks in the cowl and compressed some foam on the bottom of the nose, as well as splitting and cracking the first 12″ of so along the bottom seam of where the two foam “halves” come together. The motor box is also a bit more loose now than it used to be.

It is certainly something that could be repaired with just some glue but it would be a bit ugly and I don’t want to go to the effort of a full repaint of the body, which is what it would take to make it look good again. A new body is available and at ~$85 not out of reason. As my buddy Kelly says: “Let me know when this hobby gets cheap.” I will do quite a bit to avoid painting as I have no talent for it, nor proper equipment or appropriate paint area to do it right. Disassembly and re-installation is in my wheelhouse however! So to start, here are some pics of the damage.

Here are the cracks in the plastic cowl piece. Looks fairly fixable since there isn’t any compression… glue, clamp and go I’m hoping.

This shows the side of the cowl. As you can tell, as the cowl pushed back at the bottom, the top pulled down and forward which ripped some of the mounting points loose.

This is the bottom of the nose where you can see the split seam and cracks and compression radiating out from the impact zone.

You can really see the compression and re-expansion here.

As you see here, lots of compression further back as well.

Back edge of the canopy… more compression? Or maybe from impact when it touched down.

Time to start disassembly.

Remove this cover to get to the tail wheel steering servo…

Steering servo to the right, retract left… screws holding retracts already removed.

Remove the springs from the landing gear doors before removing the doors.

If you flex the doors, the pins can be popped out of the loops without damage to either.

Removal of the Horizontal stabs is a simple matter of removing 4 screws.

Remove these two screws in the rudder to remove the rudder horn. Pictures on line seem to indicate this part may come with the new body but just in case…

Remove these two screws in the rudder to remove the rudder horn. Pictures on line seem to indicate this part may come with the new body but just in case…

Here’s the distribution board that drives all the in-wing electronics. The two white connectors feed the wing root connectors. Port side connector feeds to Starboard wing and visa-versa. 4 screws hold it to the mounting plate.

Here are the servo wire connections to the mixer board for reference.

The distribution board screws through these three layers of plywood. Notch out portions to the rear. The lowest one is glued but can be pried up with some effort.

This is the magnet that holds the rear of the canopy on (except when a 2lb battery slides out with the help of a couple/few G’s of force and pushes it off!).

While you are there remove the servos and the linkages by unscrewing the clevises at the elevator and rudder and pulling them out from the servo end.

This is the wing root connector. Held in with 4 small screws. Wires fish through without to much effort… re-fishing them through looks easy enough.

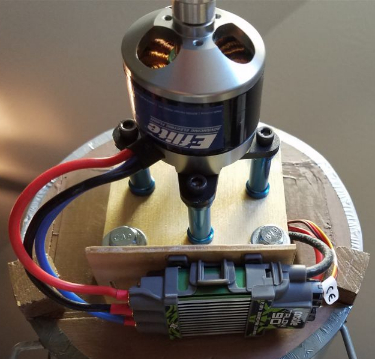

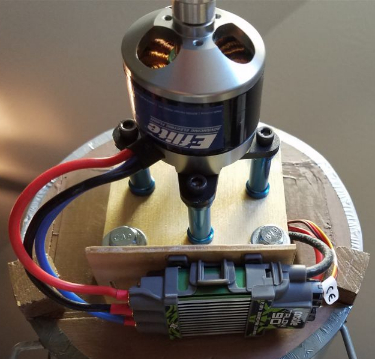

Aside from that, removal of the motor and speed controller is pretty straight forward. The speed controller is very easy to remove if you fail to properly secure the battery and do some negative G maneuvers!!! (To soon?)

Reassembly to come… I hope!

Last weekend I managed to get out and put some flights on the 1500mm FMS P-47 Bonnie… The short version is “very nice”! Here “we” are after a couple of flights.

I’ve always had a soft spot in my heart for the mighty Jug for a couple of reasons. The P-47 is a workman like craft. She’s big and heavy, not the sexiest but she is powerful, deadly and protects her pilot. P-47s were built in two places and one of them was the plant in Evansville, IN where my grandfather (mother’s side of the family) helped to build them! There are family photos from the plant (which later became a Whirlpool plant that created lots of consumer appliances) showing gun testing going on in the middle of the night using tracers! This was a 24×7 operation so darkness could not halt the process. I can’t imagine living nearby and listening to those 8 .50 caliber machine guns going off at 2AM! Just another hardship of war I suppose. Most of those families probably had folks working in the plant and so understood well what was at stake. In honor of grandpa, I added one customer graphic, making him the crew chief on my P-47. His name was Jesse A. Lane.

With Grandpa taking care of the mechanicals, I got in a total of 5 flights that day and the plane performed well. She has a wide flight envelope from nice and slow to fairly impressive high speed passes. She kept up with an EDF that happened to be in the air during one of the flights and at the same time slowed down nicely with medium flap settings. Gentle/slow landings combined with the ability to fly the plane fast enough to be convincing (a fighter should not spend a lot of time just floating along should it?). This is a somewhat rare and welcome for a war bird and gives me hope that I will fly this more than “once in a while” as it makes the plane actually enjoyable to fly versus flying like a kite or white knuckle landings being the norm.

I still have some tuning to do… need to adjust the elevator to flap mixing and adjust my throws and expo settings to my liking. Also need to double check that motor box “flexibility” that I noted in my first post on this airplane. I may have imagined it, or it may just be a result of the down thrust built into the airplane, but it seemed as if the plane would push downward with application of full throttle. Not a drastic issue and perhaps if I can firm up that motor box this would go away?? We shall see.

Overall, I am very happy with the flight characteristics and overall performance of this airplane. It is the first war bird I’ve bought that I am looking forward to flying frequently in the near future.

From a non-flying perspective I did my usual cut outs from a styrofoam cooler and created a cradle and I purchased some wing bags to protect the soft foam, guns, etc… That works well as long as you actually tie the cradle down in the trailer!

The soft foam continues to be a concern so continued care is necessary but so far I’ve managed to keep bumps and bruises to a minimum. Also, the wing connectors are holding up so far but I only have a dozen connects and disconnects on them so far so will have to watch those as well. It’s also worth mentioning that the retracts have performed flawlessly up to now. I attribute part of that to the fact that she lands pretty easily so they aren’t getting the abuse that a heavier bird would put on them.

Overall I am very happy with this aircraft. FMS seems to have done a great job and I recommend you get one for yourself if you are so inclined.

After months of serious consideration, comparison and reading hundreds of comparison posts I finally pulled the trigger and picked up the 1500mm P47 from FMS. As usual, my local hobby shop got me a great deal and in a few short days I had a rather large box full of airplane in my shop.

Bad :

Good:

Questions

Let me expand a bit on the above in reverse order… First the questions.

There is a nifty connection plate and mating plug where the wing root meets the body. Since the wing inserts into pockets and has two aligning rods, the connectors meet up perfectly and seat together snugly… or at least it appears so and they work nicely right now. There are a few reports of issues with this connection. Folks have had a few intermittent connections and the like. Some people have avoided or resolved this issue by loosening the mounting screws on the plate mounting in the body. I think the idea is that if the mount is not rigid, vibration and the like won’t cause an issue. Should I pre-loosen these or wait for an issue (and hope I don’t crash when/if it happens)?

Carrying this plane is going to require some thought. I can’t leave it assembled… there simply isn’t enough room in the trailer… but like a number of other planes the main gear is in the wings so once you take those off that round body there will have to be some sort of carrier created to keep the plane from becoming a hangar casualty!

Now for the good stuff…

The color scheme chosen for the bird has enough color and lots of striping so that it should be very visible in the sky and orientation shouldn’t be to hard to track. The cockpit has some nice touches and the wingtip lights are nice and bright. While not every panel line is captured, a vast majority are there and while they may be a bit more pronounced than needed it adds to overall look of the airplane. From a few steps away, the plane shows nicely.

The weight of the aircraft is on the lighter end versus what i would expect from a warbird of this size so I’m expecting some good flying and landing characteristics, especially with flaps being available. I doubt she will float, but I don’t expect to have to make super shallow landings at high speed that require huge amounts of runway either. With the flaps deployed I would think a more ordinary approach will be possible, holding just a little extra throttle in to keep the wing flying.

The completeness of the build out of the box is impressive. Attach elevator linkages once it is in place and assemble and mount the prop and you are about done! Even the decals are applied in advance. There isn’t much of the “Almost” in the “Almost Ready to Fly” P47!

The electronics in the P47 are by necessity a bit complicated but as opposed to other similar aircraft I’ve dealt with, FMS has done a great job of eliminating that issue. Everything is pre-wired and connected and attaching the wings requires no messing with wires at all as the wings have a built in connector at the wing root that takes care of all that for you.

And then the bad…

This airplane is built out of some of the softest foam I’ve seen. I’ve already accumulated a number of dings and dents… some wrinkles and thumbprints in the stab just from trying to get enough force on it to assemble it. As well, the body has several dents just from resting it on my airplane stand which is made of harder foam. This may actually bode well for it’s survival but I’m half expecting it to get “ugly” quick. I’ve seen somewhere a suggestion that using a warm, wet rag may help relieve some of these but I’m worried about what that will do to the paint as well…

Speaking of the paint, it seems to have the same issue that I have seen on planes like the Carbon Z Cub. It doesn’t take much to peel or flake it off. Also there is some over-spray in some areas that occurred when the paint was applied. I could wish for a bit better application.

I have been adding some additional graphics and replacing some of the decals with vinyl and there is simply no way to get them off without peeling the paint underneath. That might be to much to ask but in some spots it amazed me just how easy it came off. I don’t want to do a full repaint so I’m only applying graphics that are the same or slightly larger than the original and doing everything I can to not lift the paint around any decal I remove… sometimes slicing it with a razor blade at the seams to maintain the surrounding paint. Luckily the vinyl is a bit thicker and covers the patchy mix of paint and bare foam that is left behind.

I have found only two areas where the assembly/build of the plane could reasonably have been improved. First is the wingtip light lenses. There is a lot of sloppy glue work inside both lenses. Unless I pull them off (which risks damaging the surrounding paint and foam) there isn’t much to do about the strings and globs of glue on the inside of the lenses. Second is the engine mount. It is obvious that the entire engine mount if flexing slightly as the motor runs up. I’m not sure if it’s just a function of the soft foam or if some extra glue would solidify this… I may eventually try injecting a small amount of expanding glue like Gorilla glue in a couple spots around the mount to see if it helps. I don’t think the motor is going anywhere and balancing the prop might help minimize this issue as well but it’s something worth looking into.

Another minor issue was on the bombs. The attachment method of the “brackets” into the top of the bombs was apparently a couple pins and spit (errr… I mean glue of course). The second time I tried to detach them from the pylons on the plane, the bombs parted ways with the brackets. A good application of Foam Tac and this problem seems to be resolved. I also recommend you always attach and detach the bombs by grasping the plastic brackets versus the foam of the bombs themselves.

I promise to follow up with some more info after a flight or two.

I was recently reading in some forums and realized that many folks misuse the often used acronyms ESC and BEC when discussing the power systems in their electric aircraft. It seemed evident that some of the folks were using these terms interchangeably and likely could not have actually defined either. So my purpose here is to define each and plant some basic ideas about what they do.

An ESC is an Electronic Speed Controller. This device is what takes power from the main battery and feeds power to the motor. The amount of power that is passed is normally determined by input provided by the receivers throttle channel output. ESCs are normally rated by the voltage range they can accept and the amperage they can pass without damage. More on these rating later. Obviously, any electrically powered airplane is normally going to need this device to control the motor speed. An ESC has nothing to do with providing power to the receiver and servos. That is the next topic.

A BEC on the other hand is a Battery Elimination Circuit. This device is designed to take the voltage of the main battery and regulate it down to a voltage that is safe for our on board radio gear. Most output around 5 Volts. The whole terminology revolves around the fact that, without this device, the aircraft would have to carry two separate batteries. One to power the receiver and a second to provide power to the motor. So this circuit quite literally eliminates the need for one of the batteries. Again there are two important ratings here. What voltage can the BEC take as an input and how much current can it provide? A BEC can exist as a standalone device (also known as a Regulator) or be incorporated into the ESC. If it is built into the ESC, it will normally provide power to the receiver via the throttle “servo wire” connection. I quote that phrase as there is no servo involved but it is using the same physical plug and wiring as a servo so that it can plug into your receiver.

Having the BEC built into the ESC is probably what causes some of the confusion as folks who do not know what the two acronyms stand for assume from the usage that they are one and the same. Understandable, but incorrect.

So, one might assume that the simplest and best way to handle powering your on board electronics is to always buy an ESC with a built in BEC. That is certainly the most common way, but there are some issues to consider.

First, you need to understand a couple of things. First is that using a BEC at all has both advantages and drawbacks. The main advantage is the elimination of a second battery pack with the attendant weight and cost that carrying a second battery involves. The main disadvantage is that you are now putting all your eggs in one basket… i.e. the only power source for both the motor and your flight controls is a single battery. If anything causes that battery to disconnect or fail, you are suddenly a powerless spectator to whatever occurs next and it likely isn’t going to be pretty!

For a vast majority of electric aircraft, this is a reasonable trade off. Chances of a problem are small and in many cases it is simply not practical to carry a second battery pack. This is really no different from most glow powered airplanes as they typically only have one battery for the radio system and a failure there has the same result. But as planes get larger and more powerful… there are additional considerations.

First, remember that BECs are rated by their input voltage capabilities and amperage they can provide. Something to keep in mind is that it is a basic truth of electronics that while it is easy to take a voltage in and reduce it by a small amount (think 2S Lipo/8.4V battery pack being regulated down to 5V) the higher the input voltage is the “harder” it is to do so (think 10S/42V pack regulated to 5V). And when I say harder I mean it is more expensive, larger and or heavier and creates more heat… none of which are good things in an electric airplane! Another difficulty is that the more current you want to design the BEC to pass the more difficult it is as well with the same design trade offs.

So aircraft that require more and/or stronger servos because they are bigger, faster or whatever need to pull more current to run their servos and may quickly outstrip the ability of a BEC that is built into the speed controller. Also since aircraft that require more/stronger servos are likely also running 6-12s power systems… The speed controllers in these planes often do not even include a BEC because the engineers designing these know all about the aforementioned limitations and aren’t going to include a BEC that is unlikely to be of any use in the aircraft for which the high powered ESC is designed!

Finally, one often overlooked rule of physics/electronics is that servo wires/connectors are not designed to carry more that ~5A continuously and therefore providing a much stronger BEC with a single servo wire to deliver the current would be silly. Note that I said continuously. Connectors and wires can handle higher current for short periods of time.

There is much more to discuss when it comes to power systems in electric aircraft but those are fodder for another post. Hopefully this article has helped some folks to better understand these two key components.

I’m constantly updating and hopefully upgrading my RC gear and recently I decided I needed a new charger. The one I bought is the Hitec X1 Pro. I bought it in combination with the Powerbox 17A power supply.

A couple of reasons I think the X1 Pro will serve my purposes.

1. Power

2. Portability

I have been doing some flying indoors as well as running an RC car at the local track and I found that my current charging options (a Hitec X4 CD charger and my PL6) just don’t fit the bill for a couple reasons. The Hitec is adequate for some needs but with only 50W power per channel it can be a bit slow for some needs and requires a DC power supply to run it which adds more weight and bulk… especially since all my 12V supplies are fairly heavy and large. The PL6 certainly has the power but it also needs a DC supply and it is a fairly pricey charger so I don’t like to drag it around very much for fear of damaging it. It usually stays in the airplane trailer or the shop.

After my buddy Corey picked up the combo X1 and power supply I had a brief look at it and decided it might be the solution. Power supply and all it is very small and is capable of charging at 180W! That means I can charge a 2S (for the car) at around 20A if I like! This could be a very quick charge for a single battery or I could charge several of my more common aircraft batteries at once with a parallel board. Even with the power supply the unit is a <6″ cube so portability is excellent as well. Another bonus is it can discharge at 30W which is better than most chargers so getting down to storage charge when needed is quicker as well. Second bonus is the price for the package. I have seen them from $130 to as low as $80 for the pair… Hard to beat even at the higher end of the price range. So I brought one home today.

When you unbox the X1 and the power box you will find that you can connect the two with some nifty little double ended banana plugs. They supplied 4… 2 are needed. I suppose they will eventually wear out so having spares is a plus. I removed the little rubber boot on the bottom of the X1 and plugged the two units together with the double ended bananas and presto, I had a fairly compact and powerful AC powered charger.

In fact, it is compact enough that I don’t think I’ll be taking it apart anytime soon so I decided to come up with a way to keep them semi permanently attached in this configuration. I can see where leaving it this way and packing and unpacking it might stress the bananas so here’s what I came up with.

First I loosened some of the cap heads on each side where they are closely adjacent on the two units. Then I took some wire and bent it around in S curves such that tightening the screws would capture the wire. Here’s a closeup.

I did this near all 4 corners and now the unit is practically one piece. Since I used fairly small, semi-soft wire I can easily take this back apart if I decide I want to modify this setup later. I may eventually make something more like a “latch” from servo arms or something but for now I think this will work well.

My only trepidation at this point is I need to find a proper box or padded bag to put the unit in to protect it when it’s in my car “satchel” where it might get rubbed against and scratched.

I have only run the charger a couple times so far but I am quickly getting accustomed to the controls (just a slight difference from most I have used).

Finally, the first time I tried to pull the connection that goes to the balance board from the charger, I had real trouble releasing the catch. There didn’t seem to be enough room between the connector and the case to release it and pull it out. I almost pulled the connector right off the pins! A razor knife took care of the pesky latch! Nothing else I have needs a latch on this connection so I don’t think I’ll need it.

So far, I think the little X1 with the Powerbox 17A is going to be a welcome addition to the charging lineup around here. I have seen some indications that they may soon do away with this charger and power supply! I hope not as it seems to fill a niche for me and think others may be interested as well.

After swapping in the power system from an E-Flite Timber, the Windy seemed to be ready to go but then I started to notice what sounded like a stutter on startup and sometimes even at higher power settings. I did some research and found a lot of speculation around causes.

Some report that connection issues cause the problem. It seems a poor connection on one of the 3 wires coming from the speed controller can be to blame. Others claimed it was a setting in the speed controller (timing) that creates the issue. As best I could determine the connections on the motor end seemed fine so I tried re-soldering the bullets on the speed controller, then replaced the wires entirely but neither made a difference. Since the motor is fairly inexpensive, I decided to try that next and placed an order.

While awaiting the new motor, I did some research and tried to program the timing on the 40A ESC that comes in the Timber. I didn’t consider this to be a very likely scenario as most Timber’s don’t seem to make this sound but I thought I’d give it a try. Based on my experience… don’t bother! I have programmed several brands and types in the past and I tried to follow the published directions to no avail. After researching on-line, I have found that this is the experience of all but a lucky few with this ESC. Remind me to bypass the E-Flite line of speed controllers in the future.

Unfortunately, in my experience, E-Flite tends to have an appalling lack of information on the products installed in many of their ARFs. This makes it very difficult to pick an upgrade part or replace a failed component, especially in the case of a part that is difficult or impossible to acquire from the manufacturer. I am quite fond of the “Power” line of motors however, but I usually stick to that product set and avoid the motors that come only as part of an ARF. I only tried this one as it was so inexpensive.

In any case, after the new motor arrived I tested and found it made ZERO difference! Back to the drawing board. The next step was to get a new speed controller. My “go to” on speed controllers has always been Castle Creations. In my experience, not only has the quality of the Castle products been high, but they offer many features that your average ESC doesn’t come with. With the Castle ESC, I can get real time or recorded telemetry, programming either through my radio or via a cable to my laptop plus features like a throttle cut switch. Yes, they are one of the more expensive manufacturers but I think they are generally worth the extra dollars. Of course I am always looking for a discount!

A few days later I found a good deal on a 50A Phoenix Edge. With a little extra overhead in the current handling capability plus the ability to handle up to 8S, programmable setting concerning timing, braking, etc… along with telemetry capabilities, etc… (I like to be able to move my gear on to other projects down the road) I cashed in a gift card to help soften the blow and made the purchase.

After soldering on the appropriate bullets and power connectors, I tested with the Castle and the motor purred like a kitten… or screamed like a vacuum cleaner gone berserk once the prop was affixed! Since this controller is not water proof I decided to take some precautions. First I hid it away in the pod to shield it from most water and second I did a quick water resistant treatment with my handy bottle of Corrosion X. I have had good luck with components treated with Corrosion X being dunked (complete submergence) and continuing to run so it has become my go to for insurance against water damage.

Here’s the dunk process to apply the Corrosion X.

Then I let it drain for 10 minutes or so.

After a quick wipe with a paper towel to remove some excess from the wires I nestled it in the top of the pod with some foam around it to keep things snug

Then I buttoned it all up and tucked the wires well away from the propeller!

In testing with a 4 cell battery, the Windy was able to taxi around on my short carpet in the shop and readily pick up speed and turn. I am looking forward to getting some test runs on the snow and later at the pond. Best guess is that I may have a bit more power than before… I’ll try to at least add a comment here after some testing. Wish me luck!

After picking up this little ducted fan at a swap I have been going over it and trying to get it ready to fly and every time I look at it there seems to be something else that needs “remediation”! First I went through the power system and had to disassemble and re-solder, etc… Then I had to re-glue the control horns on the elevator and find some mini/micro EZ links to capture and hold the control wires.

Then I started looking for replacement control horns for the ailerons. In order not to change the geometry on those (hoping the default/factory sizes are the right length) I decided I needed to create my own… So I quickly cut some out of some 1/8″ thick ply…

Then I cleaned up the holes in the ailerons and applied some FoamTac.

Here’s an Amazon link where you can get some of your own if you are so inclined. I can’t imagine working on foam aircraft much without some. It is very versatile and incredibly tough. : Amazon.com: Beacon Foam Tac Foam Glue 2oz Carded by Beacon Adhesives: Toys & Games

I made use of some dubro micro hardware for the needed linkage hardware and all seemed to be finally coming together… until I figured out that the elevators could move through about 1/3 of their travel without moving the servo!! This didn’t seem likely to result in a successful flight so I was back to remediation mode…

After some investigation I realized that this small airplane was showing that some things don’t change with size. Whenever you use a “wire in tube” type of linkage (one to each half of the elevator in this case) you must support and secure the outer tube. In the case of the F-16, the flexibility of the linkage makes it ideal to route around the ducting but makes securing it all the more important. Whoever built this plane originally didn’t do this. Unfortunately this meant I had to cut some more access holes since the plane and the power system are more or less permanently glued together at this point. Here’s one of the new holes… I tried to follow some existing panel lines so maybe they won’t be quite as obvious when I replace them.

After strategically cutting these access panels I used a bit more Foam-Tac to secure the linkage outer tube to the foam side wall of the aircraft and/or the duct tube… whatever it was already laying against. Here is the outer linkage glued to the duct tube.

Then replacing the access panels gets me back to where I’m ready to install a receiver and get this thing ready. Here it is with the panel back in place… not perfect but this is not a competitive scale bird!

Of course the airplane had some final (I hope) flaws to throw at me… As I was getting things back together, I noticed that the top and bottom of the nose area (immediately behind the nose cone) were not securely attached to each other. I cut some strips of box tape to help secure these together and once more I’m almost ready to secure all the electronics and install and bind a receiver. Hopefully I’m nearing a ready to fly status.

Like many clubs, ours has an annual January 1st get together so that we can all get a “first flight of the year”. This year featured cold temperatures, 3 inches of snow… and did I mention REALLY COLD!

When I got to the field, Mr Steve Kessler was already waiting for another member to arrive so that he would have witness to his first flight… it was about 7:30AM and sunrise was set for about 8:15 so it was just starting to get light.

After we thawed out the lock on the door to the shelter, we fired up the generator, lit the heater and then went out to get in some early morning flying in.

Here’s a compilation of some video from Steve watching me arrive and noting the chilly temp (check out that dash display showing negative temps). That’s my Timber on the left with the orange wing tip stripes. Steve had his plane sitting out side while we got the shelter ready and one of his ailerons simply froze up… So our first flight became a solo.

Flying into the rising sun while it is still just below the horizon is a lot of fun. As are the floats on the snow. Better than skis in these soft and fluffy conditions.

Later on that same day I got out the Traxxas Fiesta AWD and mounted the camera on top for some more video.

It was a bit chilly (what’s -14 when you’re having fun?) but we started the day with a beautiful sunrise and proceeded to enjoy some hot chocolate, cinnamon rolls and a nice warm shelter for between flights! Later in the day we feasted on some brats and burgers along with baked beans and some tasty baked goods for good measure. All in all, a great start to the year. Here’s hoping 2018 ends as well as it began!