A couple years ago I was taxiing back toward the pits with one of my smaller gas powered planes and had stopped to observer another flyer doing a nice touch and go… My plane was sitting by my feet at a sedate idle during this distraction. When I turned back, I returned my left hand to my radio and inadvertently slid the throttle stick to full!! Luckily I was pointed at the pit chain link fence 6 feet away with no other obstructions… like people… so as I grabbed the stick and returned the throttle to idle the plane made a dash for the fence and quit as a result of the impact and the prop breaking into several pieces. It did no real harm to anything except the prop and my pride… but it woke me up and from then on I have been much more attentive to my models while they are running. When I am idleing, my thumb is hooked across the top of the throttle stick so that it cannot easily be moved upward. As well, I now have a kill switch on every fuel powered airplane and it is always in the same position on the radio so I don’t have to hunt for it! With gas planes I have a mechanism hooked into the ignition circuit that kills power to the ignition. Depending on the type of engine and ignition system it may work a bit differently but each disables the ignition which kills a gas motor immediately.

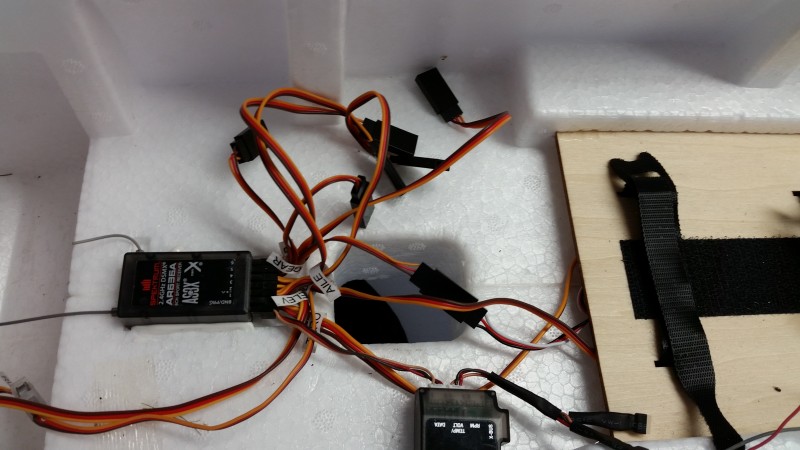

With the advent of more electrics in my fleet this became even more problematic. Electrics, once the battery is connected, should be considered to be “running” in all cases and therefore treated with the respect that would be due any idling engine. Since you can forget the battery is plugged in at times, I try to be especially careful to restrain my electric powered aircraft whenever I’m not holding on to them and a battery is installed. I have also setup a throttle cut switch that limits the throttle channel output to zero or as close as possible. In some radios this is simpler than others. In my Spektrum DX-8 there are two ways to accomplish this… maybe more… but I’ll show one of them here that I use most. (I believe the 7s, 9 and 18 all do it similarly)

Note: You can do all of the following without the plane even being present and certainly don’t want to play with this with the plane powered up! I highly recommend you test after you finish however with the plane well restrained or the prop removed.

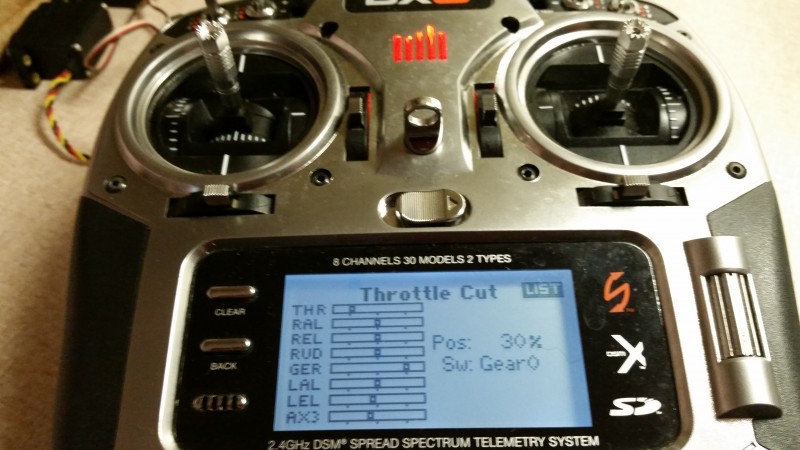

First, the DX-8 has a throttle cut option in the setup menu. If you go into that menu and change the inhibit to a switch label (I tend to use Gear0 as I’ll show below) you get a screen that looks like this.

You’ll notice that the switch is set to Gear0 (that’s a zero). I use this setting as I tend to setup my radio so that starting point for all airplanes when I fuel up or attach a battery is with all switches pushed away from me. It really doesn’t matter which way you do it. I’ve worked with computers and electronics so long and the way I was taught logic you generally consider 0 to be off and 1 to be on…. I guess position 2 is “really on” in the case of a 3 position switch!

With my radio set this way the throttle is locked so it cannot inadvertently start up without moving both the throttle stick and moving the gear switch out of its starting “safe” position. The other thing you may notice is that the position reads 30%. I played with this and came upon this setting by trial and error. I believe this has to be done because of two factors. First, the designers created this for (I believe) primarily fuel powered aircraft where the stop/kill position is significantly different from the idle/standard starting position. In an electric aircraft you generally don’t want an “idle” with the prop moving when you pull back to the lowest position on your stick. You want a full stop. Second, most speed controllers in my experience will look at the throttle setting on power up (as long as it’s at least somewhere near one end of travel or the other) to be the zero/stop point. That’s fine until you combine with point 1.

So imagine you plug in the battery with the throttle 30% lower than “idle”… which is what the throttle position would be if you left that setting at zero and had the switch pushed forward/off when you plugged it in. All seems fine… Your speed controller makes its little tunes and if you move the throttle stick nothing happens but your servos are energized (this may vary by manufacturer of the speed control). Great, you are ready to taxi and you flip the switch to the armed/on position and immediately the prop spins to a “high idle” setting!!! That’s not convenient, nor especially safe. This is because with the kill switch in the forward/off position the throttle was at a point 30% or so below the idle point and when you plugged in the controller reset that to be “zero”. By testing I have found 30% to be about the right point to avoid this issue. Now the kill switch doesn’t really change the position of the throttle at all and acts more like a throttle hold then a cut. Ideal for what we want when dealing with electrics.

There are other ways and other radios do it differently. On my DX-18 which I fly more than anything else I use the F switch instead of gear because I use the gear for other things… like retractable gears! But whichever switch you use, I suggest you keep it consistent. This way your routine on each plane is the same at least as regards to a safe “startup” and also because occasionally you may want to hit it in a hurry and not having to think about which switch it is can make a big difference in response time.

I’ll try to post on a different method in the near future. Hope this is helpful. Fly safe!

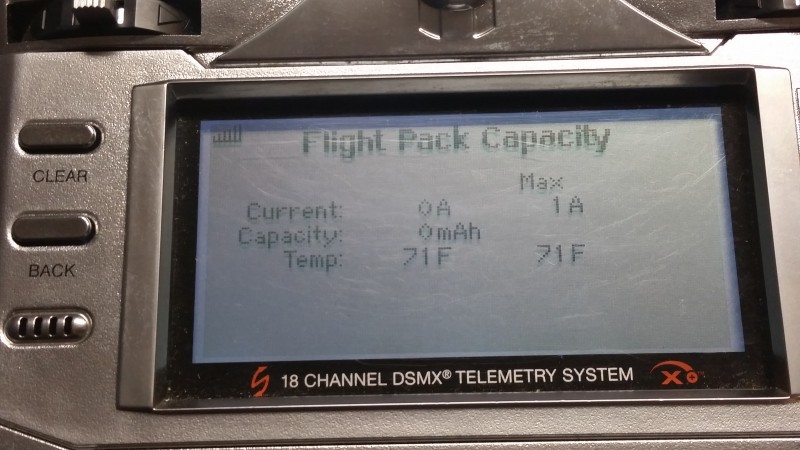

I now look forward to actually flying and testing the capacity measurement capability and am excited that I will no longer endanger my batteries by over discharging them. The closest I could do before was to set a low voltage limit which often meant I would get a warning that would sound at anywhere from 5-35% of capacity remaining depending on throttle setting at the time. I have great hopes that with this new capability I can set the alarm for a calculated 80% of battery capacity used and expect a much more accurate accounting.

I now look forward to actually flying and testing the capacity measurement capability and am excited that I will no longer endanger my batteries by over discharging them. The closest I could do before was to set a low voltage limit which often meant I would get a warning that would sound at anywhere from 5-35% of capacity remaining depending on throttle setting at the time. I have great hopes that with this new capability I can set the alarm for a calculated 80% of battery capacity used and expect a much more accurate accounting.