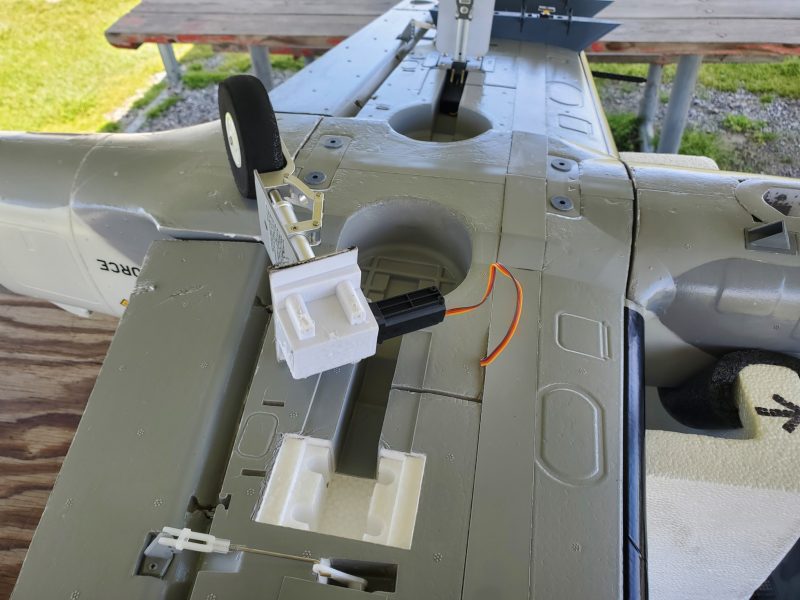

I ran into an issue recently where one of the retracts on my ST was refusing to retract. Almost every flight as I raised the gear I would notice the same one would fail to lift. I couldn’t tell for sure if it had moved at all but it didn’t look like it. Testing on the bench saw the same issue and I happened across a “workaround” where if I just waited till all the other gear were about half way up and then just toggled the LG switch to down and back immediately to up, then everything went up fully. Never had any issue putting them back down.

I even flew this way for a half dozen flights or so before I started trying to figure out a way to resolve the issue. After some testing, I found this was very repeatable in the shop and it appeared that gear never left its lock/up position when the failure occured… which was not constant but nearly so.

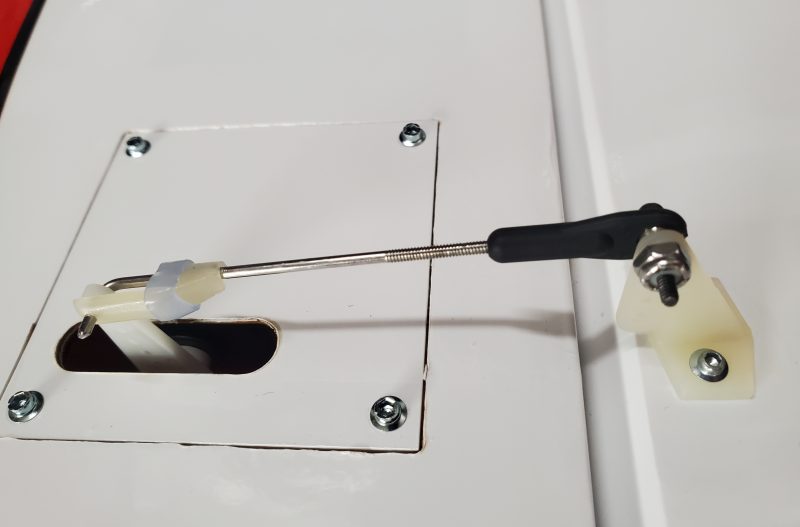

I set the plane aside for a day or two while I mulled over possible fixes. It is possible that this retract is simply not working as designed, but it works great if its the only one moving, so I’m not immediately inclined to try to get a replacement… I believe these retracts have some sort of over-current sense system that shuts them down when they reach full travel. Just like any electric motor, when they first start to move they pull a bit of extra current and they do that even more so as the hit their end postion and are phycially stopped from going any further. Its this second surge that they are supposed to sense, but this one seems to react the same way on start up as well. The retracts don’t rely on a limit switch or the like to sense the “end of travel poisition” so I began to wonder if having all the gear moving at once was causing a voltage sag/current surge that this one retract was reacting to… perhaps just a bit permaturely as that particular surge is overwith quickly and shouldn’t trip the circuit as it seems to do. There are several options I could think of that might take care of this issue.

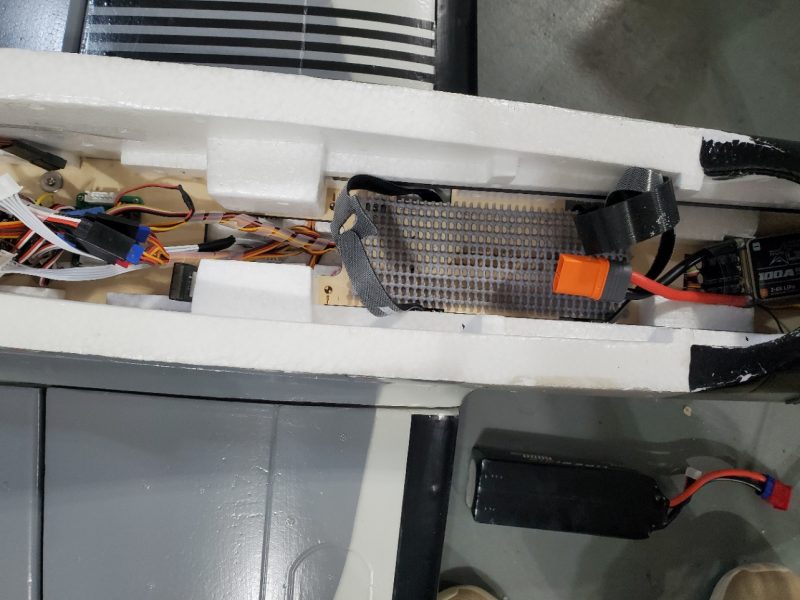

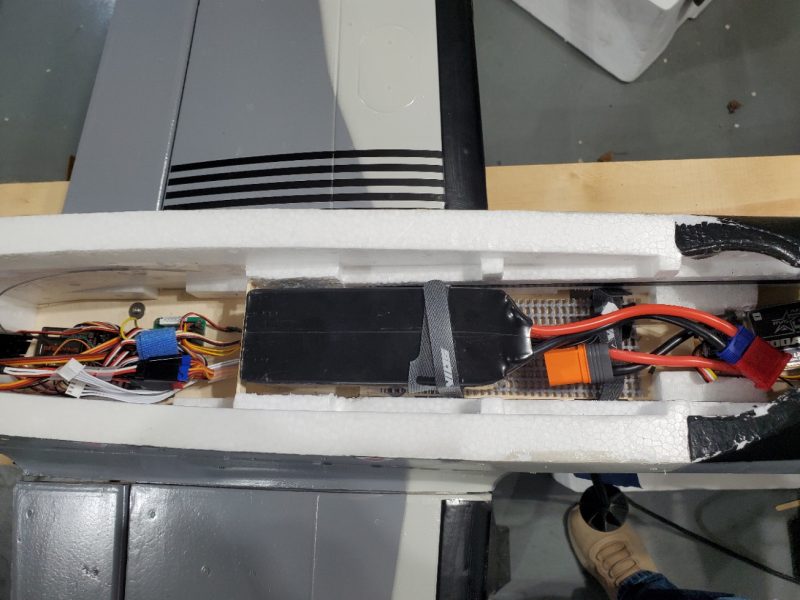

One way, would be to convert the airplane to using a seperate battery to run the retracts or perhaps the entire flight control system… everything but the motor. This would add substantial weight, which I don’t want… but I don’t like the idea that the power system might possibly being over taxed by the retracts either. Another thought was to disable the BEC in the ESC or move to an ESC that has no BEC and go outboard with something that has a higher rating. Yet another thought was to get a meter in line to measure the current draw to that retract but it seemed like that might be a bit of a project on its own, so I tabled that option for further consideration.

I was working on another project and involved in one of my many “search for a needed item” scavenger hunts when I ran across a capacitor laying in a drawer… that gave me an idea and I redirected my search to find something I knew was elesewhere in a drawer but had never used. In amongst my servos, receivers, telemetry sensors, etc… there was a little electrolytic capacitor already wired to a servo plug. I had inherited it along with some other RC tools and supplies when I bought a cabinet of parts from another modeler, some time back. It is meant for exactly this sort of thing. Some people call them “glitch busters” or “smoothing capacitors” etc… but the idea is that a properly sized and rated capacitor can help maintain the voltage when there is a brief spike of draw in an electrical power system like we have in our RC aircraft. Think of it as a small reservoir of excess current available only for a very short time when needed… like when all my retracts decide to move at once!!

Below is a typical example:

What the heck, it seemed like an easy enough test so I collected the little “capacitor on a servo lead” and plugged it into the Tucano via the distribution/control board for the retracts. These are typically Electrolytic capacitors, so be wary of the polarity! This type of capacitor can literally explode and spew out noxious materials if plugged in reversed! Bench testing showed a complete remediation with 5 cycles up and down with zero issues. Flight testing at the field since has shown that issue simply no longer exists.

I probably should look at measuring the current draw on that retract and comparing it to the other side but with such an easy fix, I doubt it has a major issue. My suspicion is that it is likely just reacting to quickly/at a lower draw/voltage level then the other two in the airplane and the current draw to that unit is likely no higher than the others so unlikely to cause any issues. If that weren’t the case, I don’t think this minor tweak would have been successful.

Just a quick tidbit in case anyone runs into a similar issue.