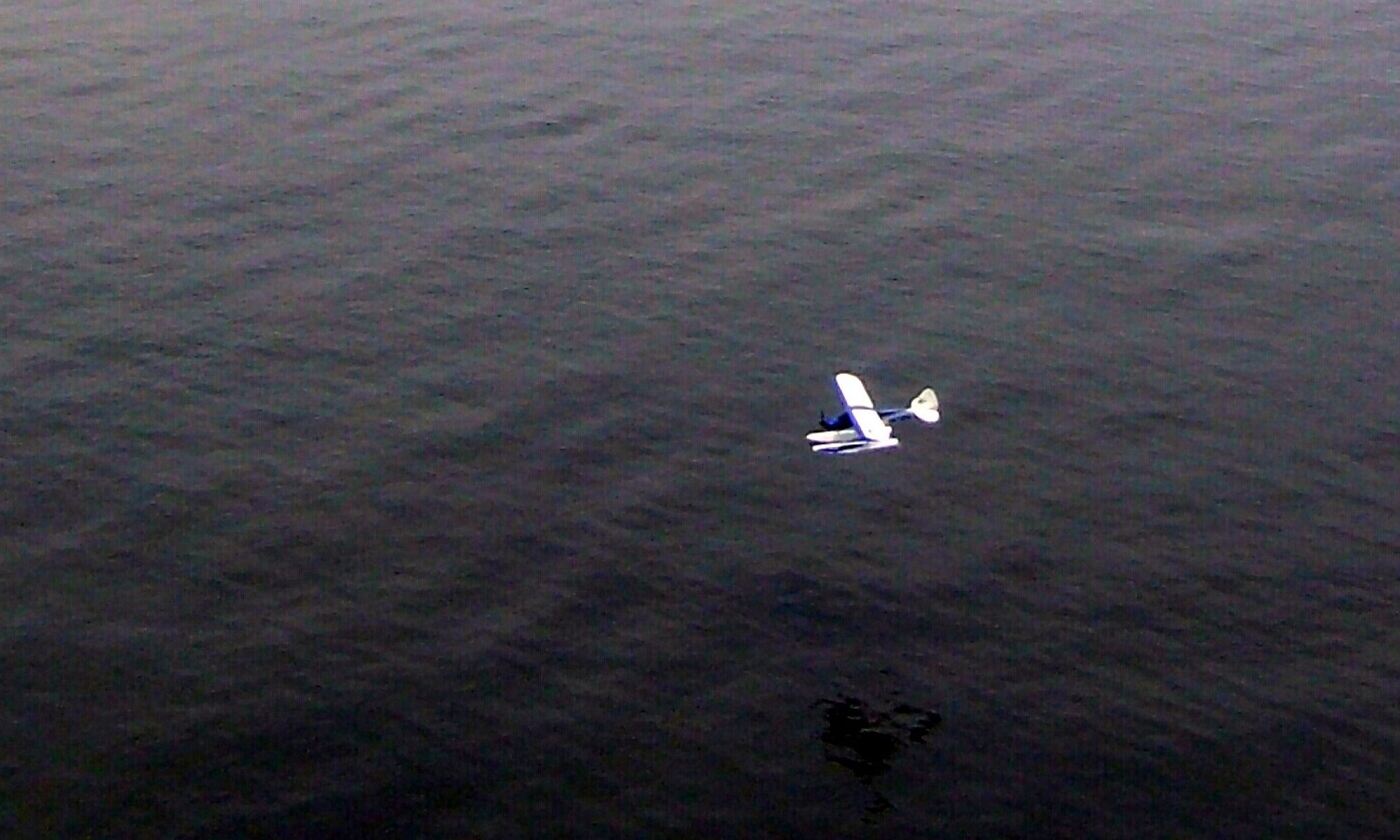

Myself along with a couple of other flyers at my club have taken to doing a bit of glider flying of late. A couple of us have Radians while our current president (George) has a true un-powered balsa and monocoat ship. While the Radians have no trouble getting to altitude with their on-board electric motor, the traditional glider needs some external help. We don’t have a winch at the field and a high start takes a lot of time and effort to rig and takes up the whole field for a period of time. In short, we wanted a better way to get a glider to altitude.

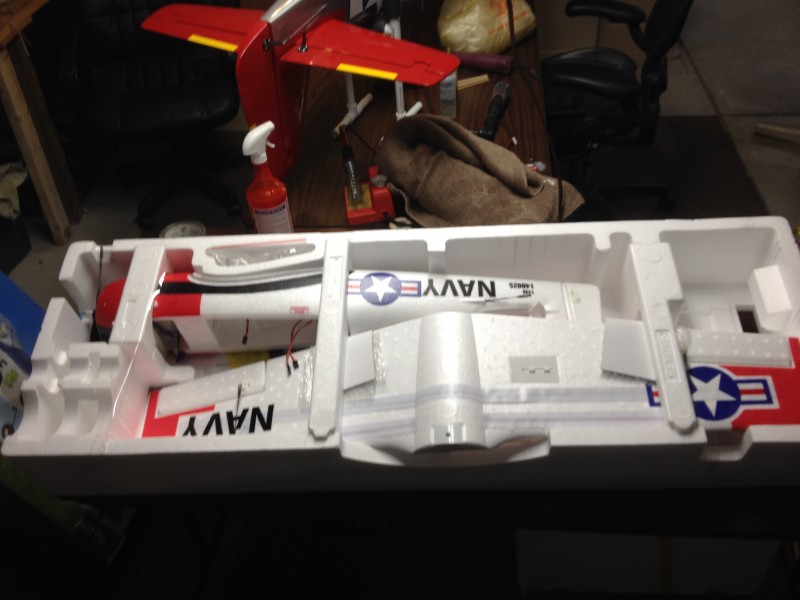

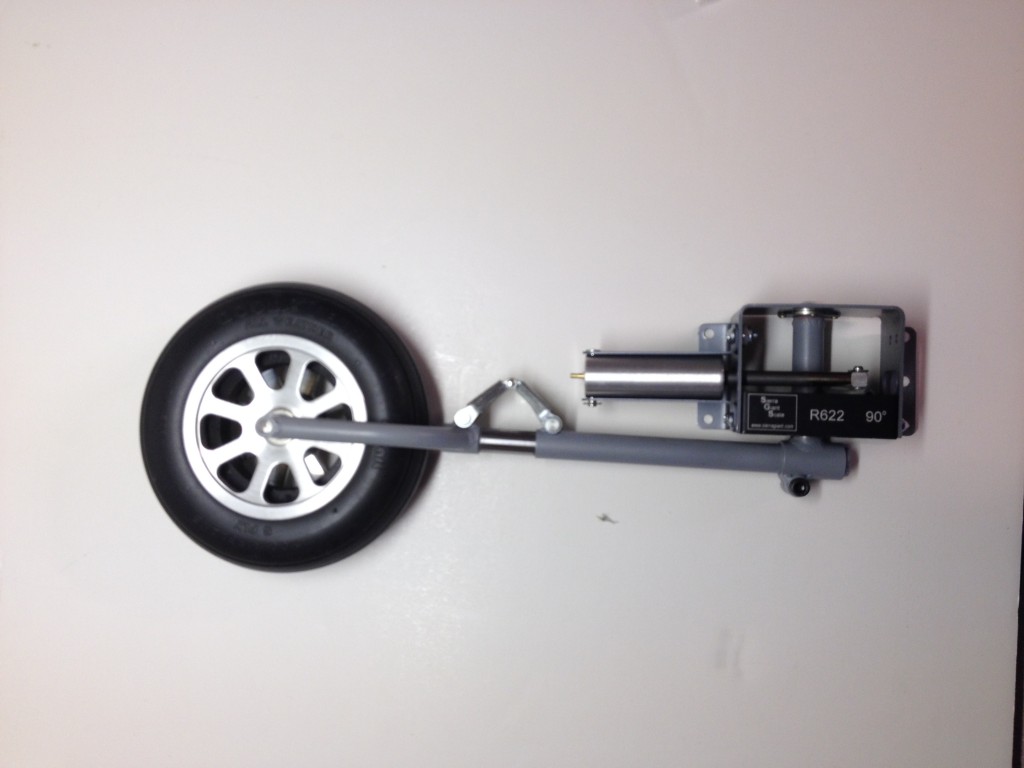

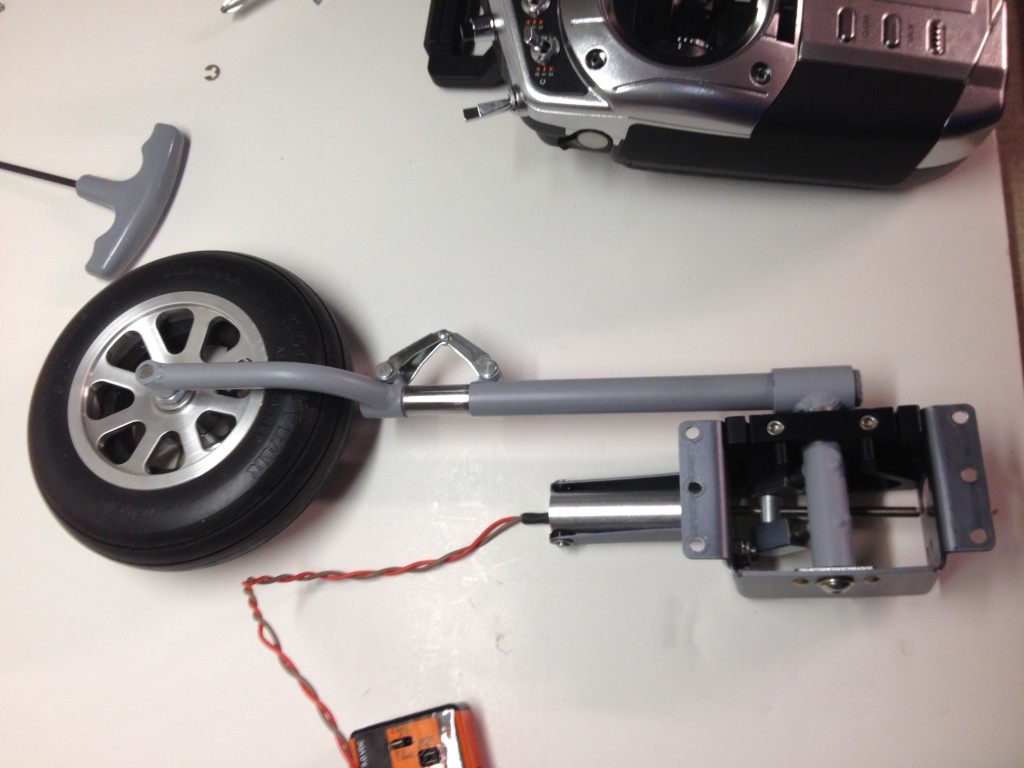

We discussed doing a tow but that seemed to require to many modifications and complex release mechanisms… While it looked fun we decided that a “carry” to altitude might be a better solution…. and it so happens I had picked up just such a mechanism at a swap meet a couple years ago. I pulled it out and got to work to get it in “ready to fly shape”.

Of course life is never that easy and I immediately found a couple issues. First, the unit had developed some warp over time and it seemed a bit flimsy. It also doesn’t fit the top shape of my Telemaster’s wing. That last I’m hoping to hold off for another time. For now, I hope a bit of foam will help to distribute the load until I can come up with a better solution… if all else gets worked out!

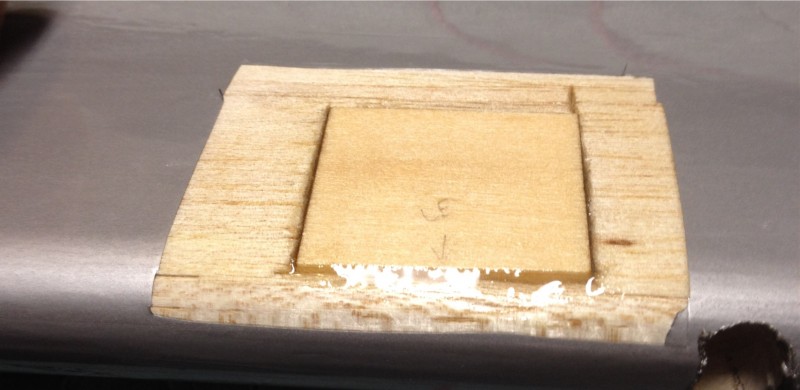

So first things first, I started out by dis-assembling the carriage and doing some sanding to expose the wood so I could bond on some reinforcing. For this I chose some carbon fiber tape from Dave Brown models that I had picked up on a whim at a hobby shop I recently discovered while on a business trip to Cincinnati. I had never used this product but the instructions were spot on, recommending tape to bind the ends, etc… I think you’ll do well if you just follow the included directions.

Here are a few pics showing the process…

Here is the disassembled structure. Note that one of the bolts that form the pivot twisted off during the dis-assembly process..

This is after sanding. If you don’t get rid of the paint and open up the grain the epoxy won’t stick and the carbon fiber reinforcing will just peel off.

Here is the cutting and fitting process. The tape is vital to holding the carbon fiber together during cutting. Remove it just as you lay the CF onto the epoxy. By cutting all lengths before mixing the epoxy I managed to do one whole side before the epoxy started getting gummy.

Here is one side with the CF laid down and weighted down so it dries straight. Maybe not as neat as I could be but I think it will serve the purpose.

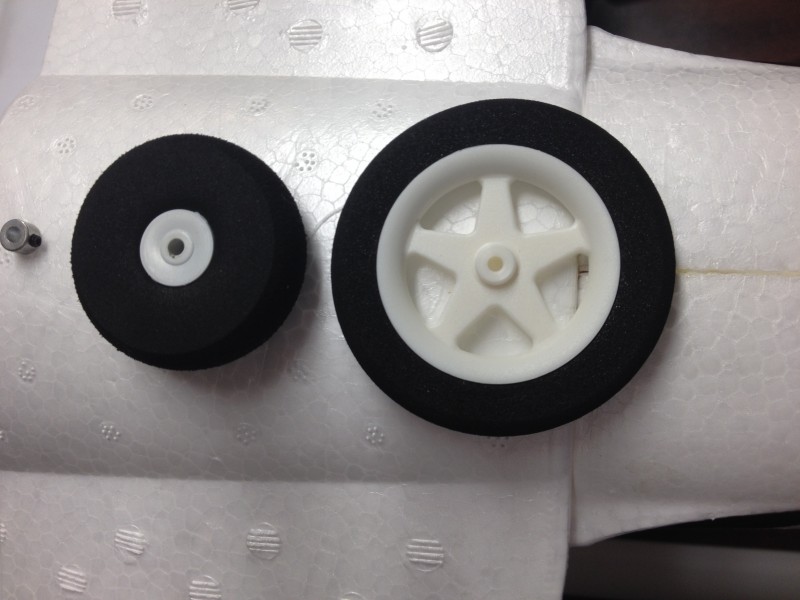

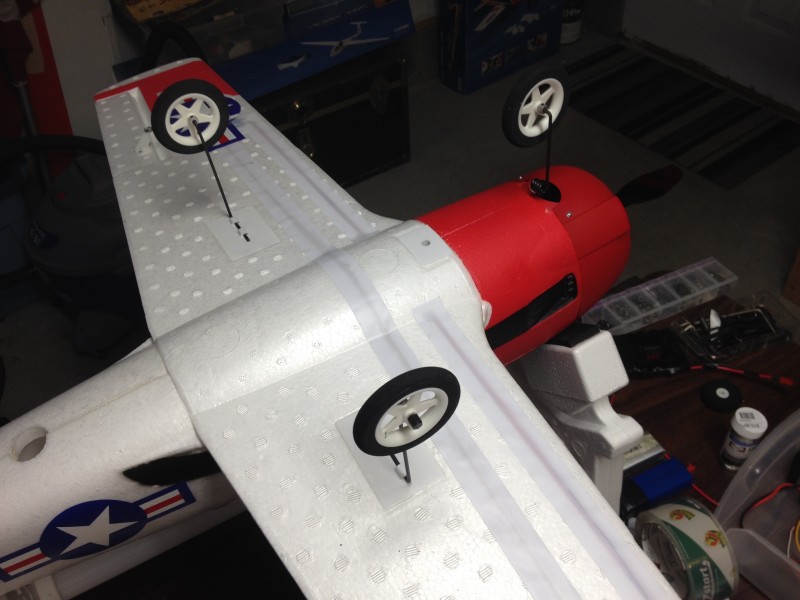

After letting this dry overnight and reassembling I did some tests and things were not working well. The glider would scoot back on the cradle and the rubber bands would slide up against the front of the carriage. This caused release to be unreliable. One side or the other would come off sooner with several seconds before release occurred after the servo released the rotating arms. Sometimes it would be several more before the other side let go. That could cause major issues. I tried polishing up the leading edge of the wood and even waxing it but that proved to be insufficient.

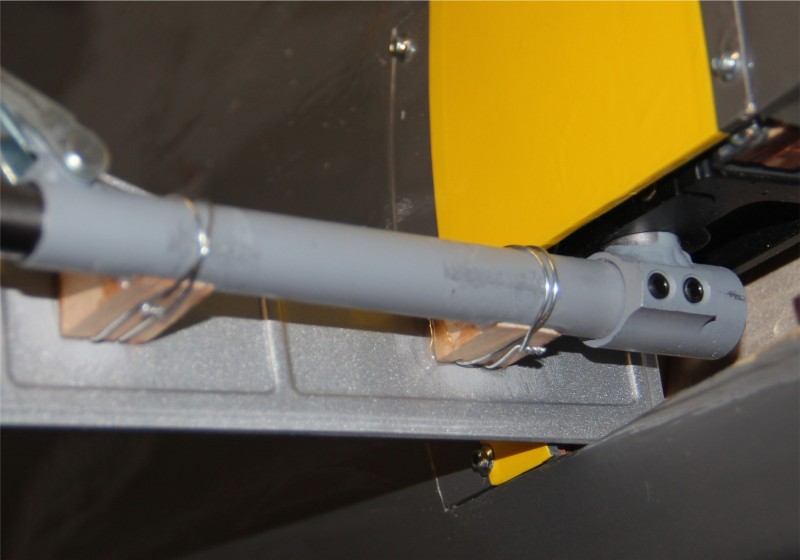

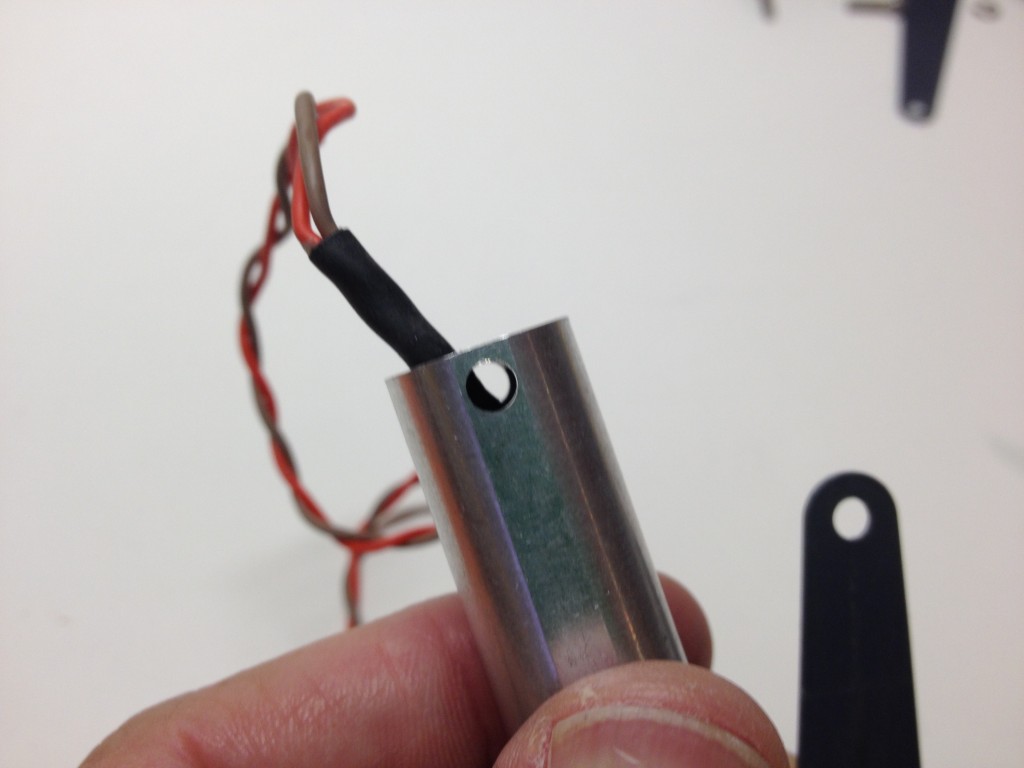

Here is a picture of the hold down system… The bands won’t stay out in the indent area of the release arms. The bands rub on the wood and release is iffy at best.

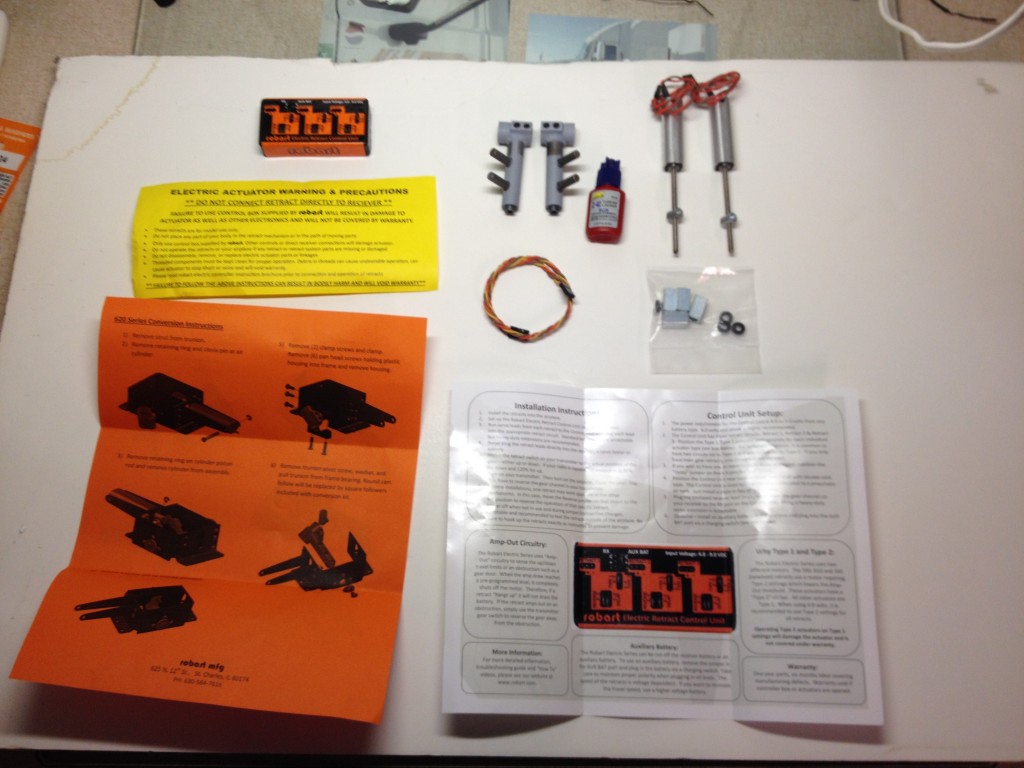

Realizing I needed to get the rubber bands to stay in those indents at the ends of the arms, I realized that the direction they were pulling had to be adjusted. No amount of sliding the glider forward or careful routing of the bands would make that happen so I decided I needed something to redirect the bands around to reposition them on those release arms.

Here is my fix… A peg (really a bolt held in on both sides with nuts) to redirect the rubber band up and over so that it stays in the indent of the release arms. Now the release is immediate every time.

With this modification I think I am ready to test the carriage with a glider aboard. I’m guessing on how many rubber bands are needed to hold the carriage in place, how many to hold the glider in place and really about everything else as well. Planning on a test run or to with the Radian perched atop the carriage tomorrow evening. Look for another post with some pics soon with the results and reports on how it went.

If all goes well, George’s glider will be next on the list. Wish me luck!

![IMG_1644[1]](http://flyrc.info/wp-content/uploads/2014/09/IMG_16441-800x600.jpg)

![IMG_1646[1]](http://flyrc.info/wp-content/uploads/2014/09/IMG_16461-800x600.jpg)

![IMG_1649[1]](http://flyrc.info/wp-content/uploads/2014/09/IMG_16491-800x600.jpg)

![IMG_1653[1]](http://flyrc.info/wp-content/uploads/2014/09/IMG_16531-800x600.jpg)

![IMG_1659[1]](http://flyrc.info/wp-content/uploads/2014/09/IMG_16591-800x600.jpg)

![IMG_1660[1]](http://flyrc.info/wp-content/uploads/2014/09/IMG_16601-800x600.jpg)