Heading to Toledo to Weak Signals tomorrow. Always fun to see all the new products and get a chance to see what’s hot.

P-51 Red Tail – Two Starboard Ailerons??

I’ve been spending a bit more time working on the replacement wing for my Giant Scale P-51 Red Tail Mustang. After cutting out the covering appropriately and recovering the tips in red and adding the yellow stripes I started working on linkages. When I went to attach the control horn to the port side aileron I discovered that there was no hardwood mounting plate on the bottom of the aileron to mount to. Of course I did so by drilling a hole and then realizing the drill went in far to easily! Stopping to consider I realized there was an appropriate right and left aileron and I assumed I had picked up the wrong one… (please imagine appropriate cursing as I realized I had already applied the small red and larger yellow material to the tip of what I imagined was the “wrong” aileron, not to mention the new hole I had just drilled)

I then went to retrieve the other aileron and quickly determined that it was an exact replica of the one I had already worked on…. not good. As you may have figured out for yourself by now, they should NOT be duplicates. In particular the port side aileron should have a hardwood plate in the appropriate spot to mount the control horn (close to the inboard end of the surface on the bottom). The starboard side aileron would have a similar plate but because these surfaces are tapered the two are mirror images, not duplicates. What happened, it appears is that I have two ailerons that would both work on the starboard side but not the port side. Here is a picture of the two ailerons side by side (you can see the half-circle hardwood plate through the material if you look closely).

I double checked the flaps and they are fine but the ailerons I have are not. Either the plate was simply installed on the wrong side or I have two starboard ailerons.

Not caring for the option of calling the hobby shop and/or Top Flite with the inevitable delays that would ensue before they came up with a replacement part, I decided I needed to correct this issue. Don’t get me wrong; they are all good folks and I feel confident they would do all they could to help resolve the issue but what are the chances they have an extra port side aileron laying around? It took months to get the replacement wing the first time. The balsa is certainly not going to be sufficient to hold the control horn screws securely for this big heavy bird so some surgery was in order. It was time for the “modeling” part of the hobby!

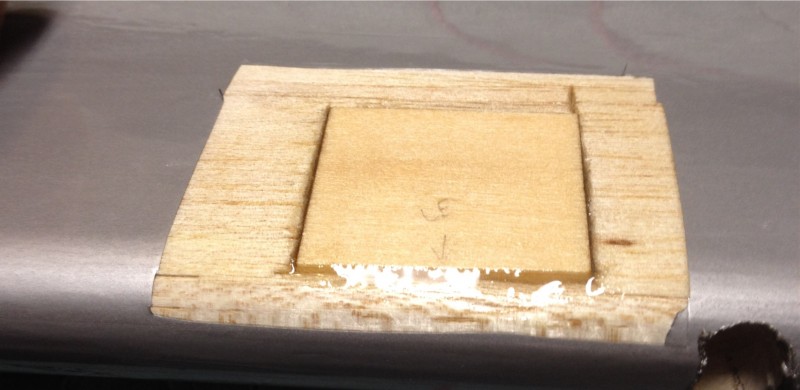

I located a small piece of 3/16″ aircraft ply from another project and cut a nice square out. I noticed my old wing used square insert and the new one uses the half circles so I figure either works as well and I can cut squares easier than circles! I then cut away the covering material around the area I had to work on and used the ply square as a template to mark the surface. Using an X-acto knife I cut around the block and then carved away balsa until I could fit the ply block in place.

Once satisfied with the fit I mixed up some 15 minute epoxy and coated every surface that would have contact with the new block with epoxy. Once in place I wiped the excess epoxy off with alcohol and set the piece aside to dry. With some minimal sanding and a bit of patchwork covering I should be able to get back to making some progress tomorrow! Here’s the repair awaiting some recovering work.

One lesson to take from all this is to keep the ailerons,flaps and whatever other parts of your ARF came partly assembled or packed together… together. If the ailerons had been correct I still might have picked up the wrong one and run into this same issue. Marking them might be a good idea if you are going to be disassembling and reassembling things.

I wonder if somewhere out there is someone with two starboard side ailerons on their Giant Scale P-51??

Thinking Saturday will be shop day. Lots of winte…

Thinking Saturday will be shop day. Lots of winter projects to be completed

P-51 Red Tail – Main Gear wheel pant attachment. A better way?

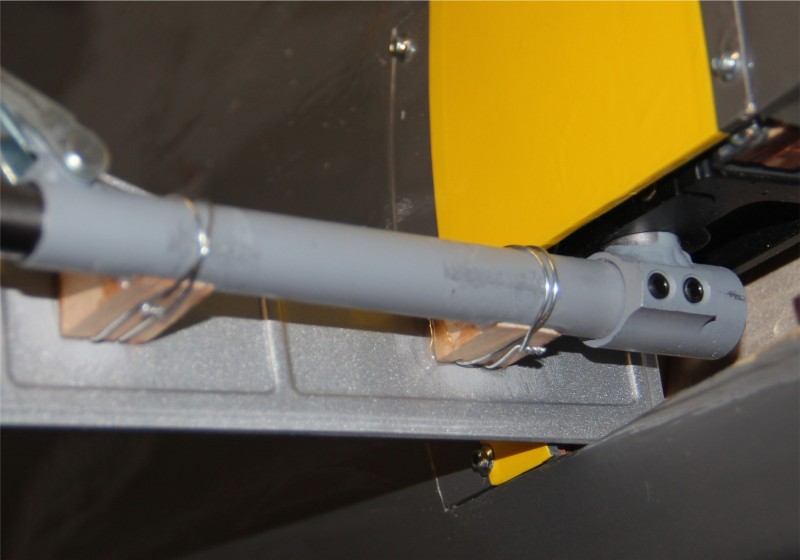

After my off field landing I decided to assemble a replacement wing. I’ve been working the replacement wing a little at a time. The latest project was to attach the wheel pants/doors to the Robart retracts (electric conversion). The manual directs the builder to glue these wheel pants on with Epoxy but that seemed like it could be a bit weak. Maybe I’m just overly cautious, but I thought something a bit more secure might be in order. I couldn’t help but think if it didn’t pop loose between the attachment blocks and the wheel pants it would surely vibrate off on the other end between the blocks and the struts themselves. Here is a view of my “improved attachment method”.

I sanded the back of the fiberglass door and the strut then used epoxy as directed but added some wire to hold it tight against the strut. In order to keep the wire from causing a gap I had to cut a couple of grooves across the top of the blocks as well. Here’s a view of both blocks in place.

I used one continuous wrap of wire rather than two separate wraps, thus the crossover you can see on the lower end (right). That seemed like it would, at a minimum, keep the blocks attached to the struts but what about the wheel pant attachment to the blocks? On that end I decided that a button head screw would add at least a bit of extra hold while also holding things in alignment while the glue hardened. Below you can see the view with the gear up. You can clearly see the two button head screws (#2 x 3/8″ I believe).

Hopefully between all of these modifications the wheel pants will stay put. Lots more work to do but with the gear in and pants in place it feels like I might be closer to finished than just getting started.

Picked up the new Vario sensor for my Spektrum Tel…

Picked up the new Vario sensor for my Spektrum Telem setup in Radian glider. Shop testing. Seems pretty cool with DX18 beeping up a storm!

Cable Ties, spiral wrap and RC aircraft wiring

I’ve always been a proponent of wiring being tightly tied down on an RC airplane. You certainly don’t want the wires to flop around and catch on servo arms, linkages and the like. This would likely result in the wires pulling loose, abrading against the internal structure of the plane or just breaking due to repeated bending. Worst of all if the wire starts to break inside the insulation where you can’t see it, the connection is likely intermittent and therefore difficult to troubleshoot.

Usually folks control this by tying the wires to the internal structure with cable/wire ties. These are usually made from flexible nylon with locking teeth built in that make them hold nice and tight and just about impossible to loosen. That’s all well and good but take a look at what happens when you pull these up, perhaps a bit to snug, against your servo wires.

As you can see the insulation on the red and black wire (for instance) has been pinched and cut through down to the conductor. It’s not impossible that somewhere down the road these two wires would touch or simply be cut and as a result a short or open circuit would occur with unfortunate results. Since this is the power lead on an ignition for a small gas engine… at best an open circuit occurs and the engine quits unexpectedly. At worst… well the flaming parts of airplane falling out of the sky probably won’t win you any “Club Member of the Year” awards. (Hey, I did say “worst”)

So my suggestion is this: Continue to use wire ties as needed but only do so with proper protection around the wires. For instance, wrap the wires first in a spiral wire wrap like the material provided by the ignition manufacturer. Then use your cable tie and tighten it down just enough to get a good grip on the wrap material. Something like this:

This wrap is also useful to protect the braided ground wire on the outside of the spark plug lead from getting abraded by the edge of a fiberglass cowl. You only want to protect the necessary part of that lead however as this nylon material is typically not made to withstand the temperatures of your exhaust or cooling fins on a gas engine. Here is an example:

Of course, this is just one option. I’m also a big fan of Velcro but that’s for another post.

Just added some content to the new tips sections o…

Just added some content to the new tips sections of the articles page of my website. Check it out at flyrc.info/articles

Building the Top Flite Giant Scale P-40 – P3 Canopy Mounting

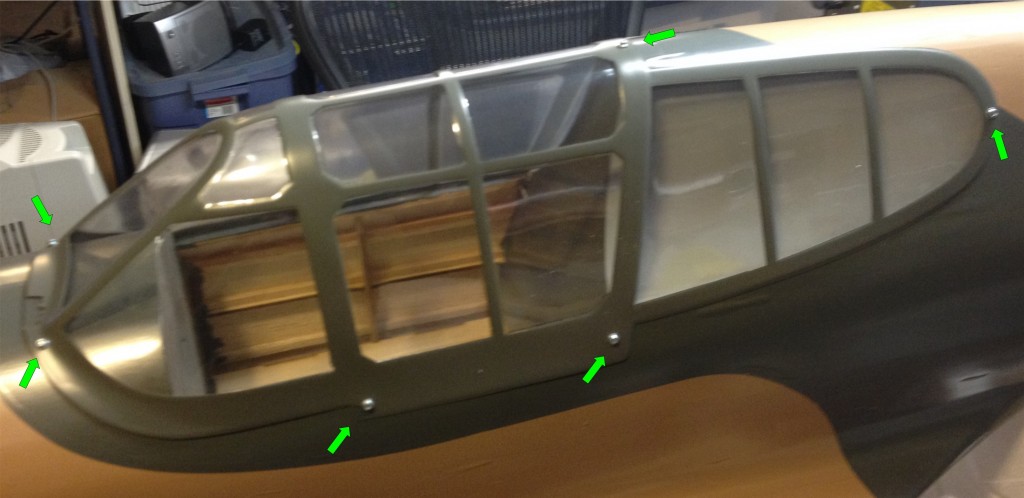

Today we tackled the mounting of the canopy on Kelly’s P-40. Of course the manual directs the canopy to be glued down but we agreed that doing so just creates a problem. With a detailed cockpit and a pilot that can turn his head, it becomes almost a certainty that the canopy will have to be removed once or twice so gluing it down is just not an option. Magnets didn’t seem to be a good option for this large a canopy on a big plane like this so screws seemed to be the best option.

The issue with using screws is there is not a lot of structure to screw to, so a bit of reinforcing is in order. We tried to use less screws this time as we thought it was a bit overdone on the last model. First we placed the canopy on the model and determined where to drill holes. After that, we taped down the canopy and drilled pilot holes before running screws down to see where the reinforcement is needed. Here it is at that point.

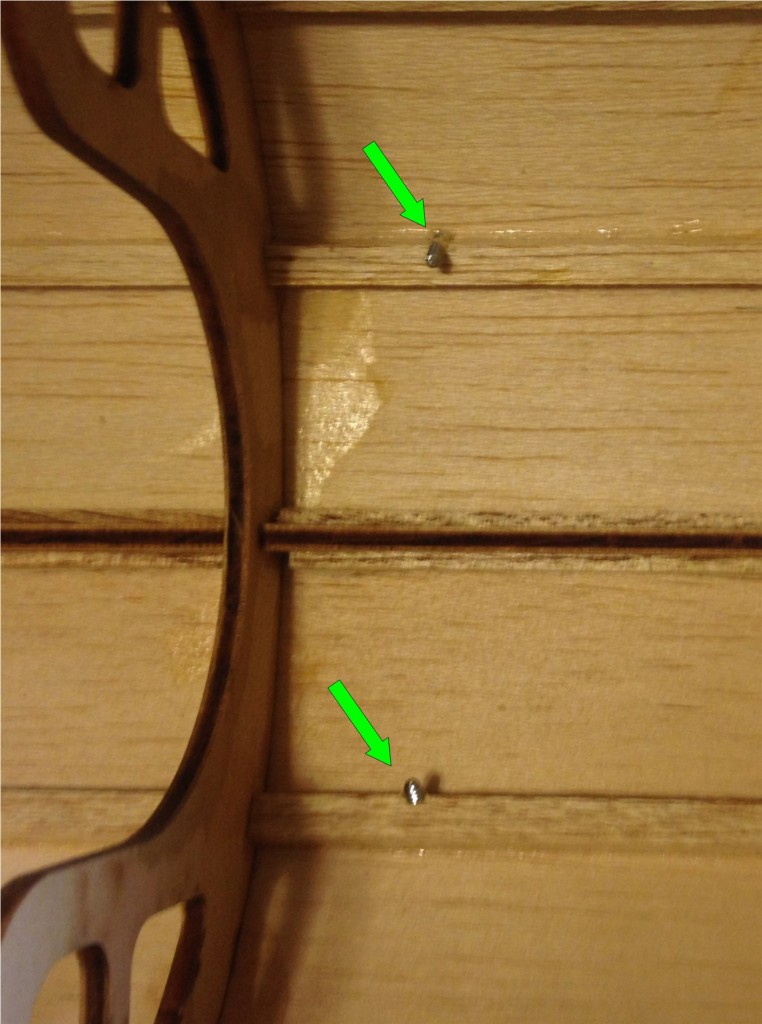

I have marked the screw locations with a green arrow in this shot and of course there are two more on the far side that cannot be seen from this angle. As you can see, the front two are at least mostly embedded in some stringers:

Just to be sure these bit well, I dripped some thin CA on the holes (after removing the screws) then used some thick CA to add a small square of “popsicle stick’ to the stringer to give the screw a bit extra to bite into.

Along the sides of the canopy we were out in the middle of balsa sheet so a similar process was used. Note that before running the screws back in you should allow for the glue to dry completely and then re drill them with a bit that is appropriately sized to open up just a pilot hole. Otherwise you run the risk of splitting the new reinforcing wood which defeats the purpose of adding it in the first place. Here is a view along the side after the reinforcement was finished.

I am hopeful that this will be enough to give us a good firm attachment and if they start to loosen up, at least there will be enough wood to drill out for inserts. I also think we will go to a true button head screw on this go round and touch them with some appropriate green paint to make them blend in better.

Once this is complete, we can work on the cockpit interior at our leisure. Once the interior is complete we can then grind down any screws that might protrude to far into the cockpit.

Next is likely to be a bit of cockpit interior or perhaps servo control linkage installation.

Building the Top Flite Giant Scale P-40 – P2 MPI Switch

This post is a continuation on the topic of the Top Flite P-40 ARF. This time I wanted to just quickly show what we have done with the MPI switch that Kelly used in his first P-40. We decided to install this same switch (which is undamaged) into the new bird but we were never happy with the location so we decided on a new position.

The MPI switch that Kelly purchased is the unit with dual HD switches, charge jacks and an integrated fuel dot. It is a fairly massive piece of hardware and comes anodized in one of several colors. Here’s a picture of the one we are working with:

You may notice that this one has an added hole right above the word Miracle… we added that in order to better stabilize the switch plate as we had it mounted in an area that was very thin balsa and curved at that. This was never a satisfactory configuration because of continued issues with it occasionally coming lose and the fact that it looked out of place on the side of a big war bird. I have some other issues with the unit as well. One that always confused me was why you would create a switch panel that has the switch “on” position being down when referenced to the lettering on the front panel?? The second is that the unit has a very complex shaped hole to mount it and MPI does not provide… not even for download… a template to cut the mounting hole for it. It is a non-trivial task to cut a proper opening and the lip available around it that allows for a margin of error is extremely small. This thing requires a bit of modeling skill just to get it mounted and that seems unnecessary to me. To bad as the MPI switch products seem to be otherwise quite high quality.

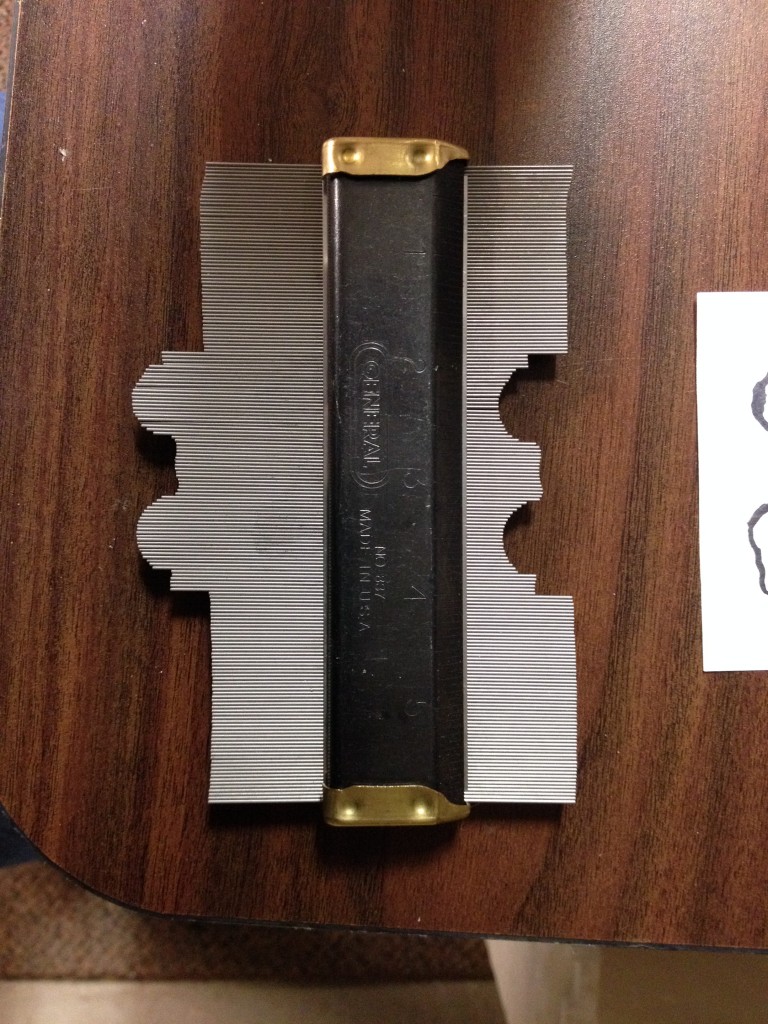

Here’s what I consider to be the necessary tool to make yourself a template for this beast:

This is a contour gauge, commonly used for transferring complex curves and the like in woodworking. By pressing this against the side of the switch, the basic pattern can be transferred to card stock. Do it again from the other side and make a few measurements to decide how far apart the two sides are and a basic template can be drawn and cut out such as the one below:

This isn’t perfect but after transferring to the selected area of the airplane and a little work with a Rotozip bit results in this rough opening. We had tested the fit and pre-drilled the mounting screw holes by the time of this pic:

After that it’s just bit of clean up and the switch drops in to look like this (note this is flipped upside down from the last pic):

When we are ready we will put the screws in place and all is well. This area is under the planes “chin” at the back of the cowl where it will be easy to reach in and feel for the switches. We were careful to arrange the panel so that forward on the switches represents “ON” and rearward is off. Likewise we will make note of the charge jack polarity before the final buttoning up happens.

This location seems like an improvement over the side of the body just below and forward of the cockpit area that we used on the last plane. That area is just light balsa sheeting while this one is ply and therefore much more sturdy. The new location is also well hidden but still reasonably accessible. Having placed fuel dots on the bottom of airplanes before I can attest that this mounting location will require much more care when fueling to avoid spillage but it is the best compromise between accessibility and functionality that we found available on this particular airplane.

Next up we will do some work mounting the canopy such that removal is possible when needed but it remains secure.

Next time we’ll do a bit of canopy work.

Building the Top Flite Giant Scale P-40 – P1 RotoFlow

Last winter my friend Kelly and I put together his Giant Scale P-40 ARF. It flew and looked great. Here’s a stock photo from Top Flite

Unfortunately, in late summer the airplane made its last flight. An engine out landing combined with some unfortunate tail winds combined to result in a badly damaged airplane. The decision was made to replace the plane rather than attempt a rebuild

While I don’t plan on documenting the whole build, I thought it might be worth posting a bit on where we decided to make a few different choices of equipment or modifications from the reccomended.

One thing we decided on was the use of a JL Products 24 ounce RotoFlow gas tank. Of course, the plane is not designed for this tank shape so some modifications were in order.

First, in order to gain enough clearance we had to trim out the former at the back of the motorbox. I should have taken a before and after picture but all I got was an after. The part that was removed was an inverted “T” shape that I’ve outlined in this picture.

Secondly, the tank neck and overflow won’t quite fit in the forward bulkhead just behind the firewall, so a “V” cut was made as seen here:

And finally, since the tank is a bit longer than the supplied unit, a bit of a trim is necessary on the radio tray that fits directly aft of the tank. Here is the piece that must be cut out.

And finally, since the tank is a bit longer than the supplied unit, a bit of a trim is necessary on the radio tray that fits directly aft of the tank. Here is the piece that must be cut out.

Once that is done, the tank fits nicely and with a minimum of padding will be a nice snug fit. This modification was done on on the first plane and now on the second. Here is the current plane during the tank fitting today.

Next time, I’ll go over the switch installation change we decided on for the new airplane.

![IMG_0931[1]](http://flyrc.info/wp-content/uploads/2014/01/IMG_09311-1024x768.jpg)

![IMG_0933[1]](http://flyrc.info/wp-content/uploads/2014/01/IMG_09331-1024x768.jpg)

![IMG_0934[1]](http://flyrc.info/wp-content/uploads/2014/01/IMG_09341-1024x768.jpg)

![IMG_0870[1]](http://flyrc.info/wp-content/uploads/2013/12/IMG_08701-1024x768.jpg)

![IMG_0882[1]](http://flyrc.info/wp-content/uploads/2013/12/IMG_08821-1024x768.jpg)

![IMG_0891[1]](http://flyrc.info/wp-content/uploads/2013/12/IMG_08911-1024x768.jpg)