Well after a short 4 flights, the original 3D printed Wolf is no more….

RIP

For reasons unexplained (I have theories but no real proof of what caused it) the plane crashed and is no more. Luckily most all of the non-printed parts are fine and ready to grace Wolf 2.

So flights 3 and 4 were both very nice until the fatal dive that ended flight 4. The wolf has plenty of power with my current setup using my 3S 1300 batteries, was balanced nicely with proper battery placement, and tracked super. Gliding was very limited, but I figured out that I didn’t have the speed controller set to brake, thus the folding prop didn’t and caused a lot of drag when the motor was shut down. So problem fixed for Wolf 2! Flaperons worked but more testing will be done on those and a rudder needs to be fitted.

After experimentation a bit with materials and printer settings I settled on constructing Wolf 2 with the following materials and modifications.

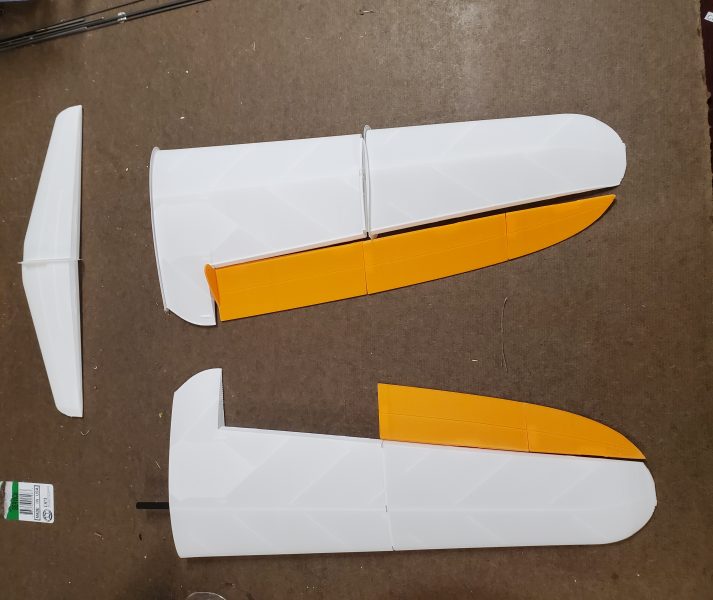

For the body I’m using Poly Light LW pre-foamed PLA in orange. It is ~35% lighter than standard PLA but still heavier than the eSun foaming LW that my first Wolf was printed from. It is easy to print as it uses settings akin to standard PLA but a bit stronger than the LW if both are done correctly. I’m also using this for the control surface just because I want that same color there to give some contrast to the white that I’ll use for the wings proper.

For the wings, horizontal stabilizer and vertical fin I’m using Colorfab LW PLA. This is very similar to the eSun I used for the first Wolf but it is much brighter white, which I prefer if I am not going to paint, which is the plan.

All parts that need to have more strength, I’ve used eSun PLA+ in either white or orange, which isn’t a terrible color match to the Poly Light.

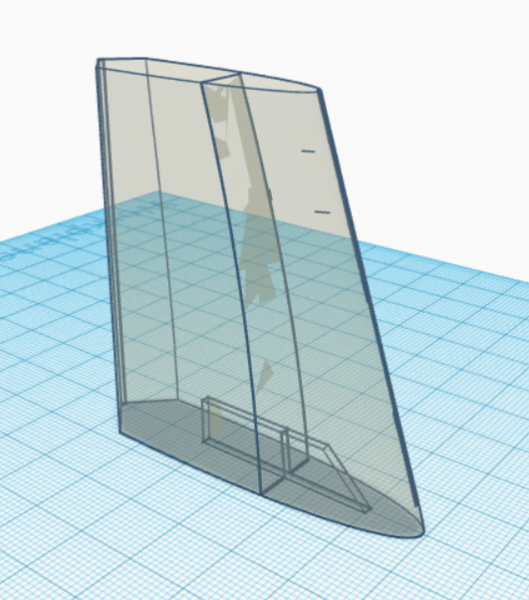

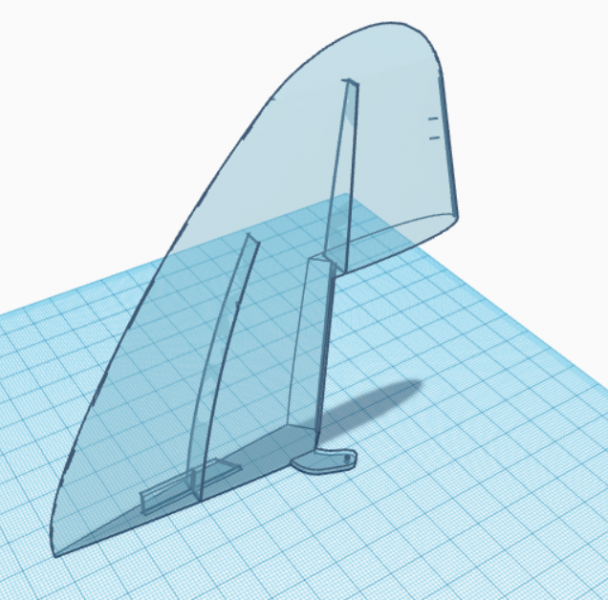

Next I needed to do some CAD work to create a workable rudder. Here are my diagrams to create the rudder versus the standard fixed vertical fin. I cut apart the existing fin and added some bevels to create each new piece then added a simple control arm on the moveable part.

Fixed Fin

Moveable Rudder

My biggest issue with this was that the structure at the hinge point was, perhaps, going to end up being a little weak. I think I need to improve these with some hinge pockets and reinforcing in that area but for Wolf 2 all I did was manipulate the vertical fin in the slicer program to do a fairly dense infill on the leading edge of the fixed fin.

I didn’t even do that on the rudder proper, instead opting for some Gorilla Glue that expands a bit as it dries to help the hinges grab to the inside of the rudder. If I ever build another I’ll probably go steal the aileron hinge pocket design and put a couple of those in the rudder and fin rather than mess with filling that area. Maybe with a small bit of bracing.

I also had to add a second servo holder in the body… easily done by just printing another servo mount and gluing to the wall under the cockpit area… and add a control rod tube extending back inside the body to the right point. That took some measuring/CAD manipulation and just good old fashion TLAR (pronounced Teelar… That Looks About Right) to get the rod guide tube in place without causing any binding.

Printed parts soon began to fill the table

And before long I had this

Pretty much ready to fly…

And here’s my rudder… working well.

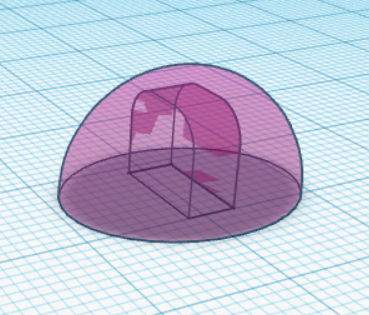

The next thing I decided is that if the prop folded it could conceivably catch on the square hatch latch that protrudes upward from the hatch cover. If it did, the motor would not be able to start up again and could cause some issues. Even if it didn’t catch a direct shot to the side of the latch could cause some problems so I designed this hatch latch cover and prop deflector.

Here it is glued to the latch.

If you do something like this make sure you only glue it to the latch and not the hatch or your hatch may no longer be removable!

After all this the aircraft seems to only weigh about 2 ounces heavier than Wolf 1 and I can now report that after 2 additional flights, Wolf flys really well. With the folding prop working correctly and the use of rudder to make slow flat turns, glide capacity seems to be increased and with a few more flights and possibly trying some smaller batteries I’m hoping to catch enough of a thermal along the way to do more than just “slow the fall”!

I’ve thought about making a removable wing version of this but I don’t want to add the weight I think that would require with all the reinforcement and mounting hardware etc… For now, as long as she behaves and I don’t do anything stupid I expect this one will transition from 3D printer experiment to just another member of the flying model fleet. What more could you really want after all?

I’ve got a couple ideas for the next model I will print and a couple other ideas for smaller 3D printed RC aircraft related projects to get started on as well so hopefully more on this type of thing will show up here soon.