After a sad end for my Top Flite P47 due to radio failure, I have been in the market for a replacement and started reading about the Hangar 9 20cc P-47 ARF. While doing some research I chanced across some posts talking about printing a new cockpit for the bird on a 3D printer… and the wheels started spinning.

Of course I know that 3D printers are too expensive, take a special brand of wizardry to operate, etc… so I inquired with a friend of mine who has perhaps 5 of these magical machines. So when I asked if he would be willing or how much it might cost to print out these cockpit he response was link to a large online retailer for a 3D printer!! Hmmm… seems like a hint. Here is a link in case you want to follow me down this particular rabbit hole.

The first thing I noticed is that this particular printer (at the time I purchased it) was under $200…. far below what I had expected. After another week of research and self justification… I placed the order.

I’ll save all the trials and tribulations of assembling the printer, testing, adjustment, more testing, etc… I decided not to have a go at printing the cockpit interior immediately. Soon enough I started finding other uses for the new printer within my RC hobby. Here are a couple of examples…

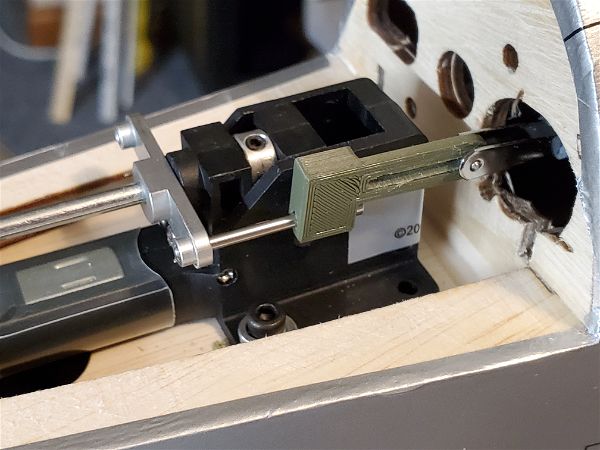

First, I struggled with getting an electric nose retract to work for the tail retract of the H9 P-47. The geometry just didn’t work with the provided linkage so I began creating a replacement, and after a few iterations I came up with a design that worked for me. Being able to change dimensions and reprint or print 3 or 4 slightly different designs and test each really made it possible for me to get this working!

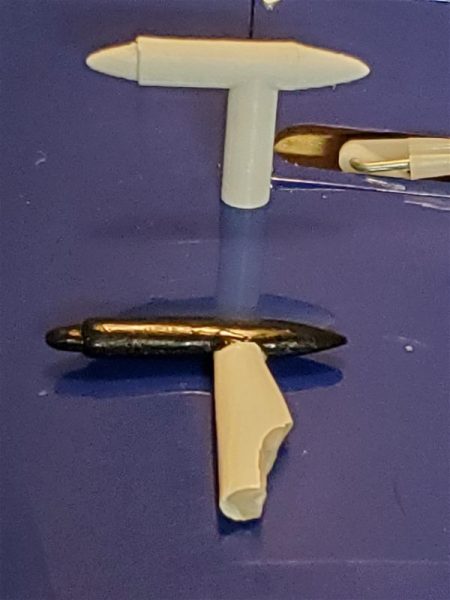

Here’s one of the early iterations..

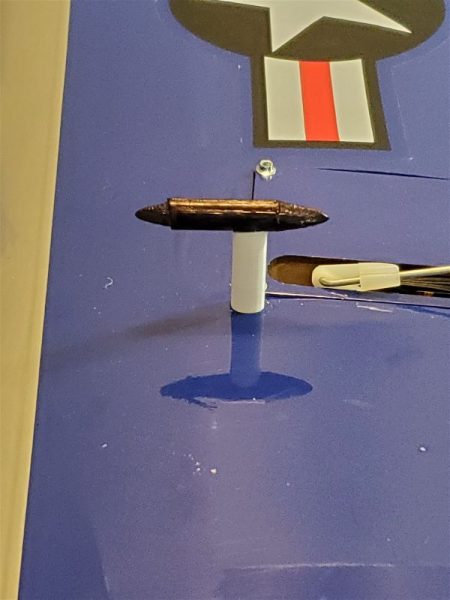

And here it is installed on the aircraft for testing.

Also for the P47, there was a pattern available to help guide the wing wiring into the fuselage for easier assembly so I printed those up and installed them immediately.

Here’s the guide tube fresh off the printer…

And here it is installed in the body of the airplane.

Next, I managed to drag a wingtip on landing on my Texan II and broke one of the scale protrusions off of the underside of the wing. I shortened my redesigned unit a bit and made some minor concessions to ease of fabrication and printed a pair of replacements.

Here you can see the broken part and a replacement part being test fitted on the wing.

And here is the new unit in place after using some marker pen to add a bit of color.

Next I found the tail wheel mounting bracket of my Tundra to be somewhat weak… a known issue at the time. I found someone had already designed an alternative, so I printed up a replacement. Actually a couple!

Here are a couple alternatives I found… The top is a bit more solid and the lower a bit lighter but how well will it hold up??

Certainly many of these things take a fair amount of time to design, prototype and print. But in many cases there are no replacement parts available or there are many options but no way to know which might actually work so 3D printing provides a way to work through the options without ordering and praying you find the right part, eventually.

So the real answer here is, Yes! 3D printing is a hobby all its own and can eat up a lot of time and effort. It can also be an immeasurably useful tool for the RC modeler. If you continue to follow my posts here, you will very likely hear more about it.